Product quality and safety hinge on maintaining your sanitary equipment. Sanitary sample valves that are widely used in the food, beverage, and biopharmaceutical industries, are no...

Sanitary Fittings Blog

We’ve compiled our best guides, product information, and industry news posts in one place.

More Blog Posts

Best Practices for Cleaning and Maintaining Your Washdown Station Hose

Best Practices for Cleaning and Maintaining Your Washdown Station Hose In any sanitary processing facility, washdown stations and hoses are essential tools for maintaining sanitary working...

The Top 5 Features to Look for in High-Quality Washdown Hoses

Top 5 Features to Look for in High-Quality Washdown Hoses In any sanitary processing facility, maintaining cleanliness is not optional; it’s critical. Washdown hoses play a pivotal role in...

Understanding NPT Pipe Fittings: When and Where to Use Them

Choosing the right type of fitting is important for system integrity, safety, and compliance. One widely used fitting style is the NPT fitting. We'll cover more about what NPT stands for,...

See What’s Flowing: A Practical Guide to Tri-Clamp Sight Glasses

Why Visibility Matters In sanitary processing, losing visual feedback can mean the difference between hitting batch specifications or scrapping a product. A tri-clamp sight glass gives...

Stainless Steel Braided Hoses: Strength for Sanitary Processing

In hygienic processing environments — whether you’re blending beverages, fermenting biologics, or packaging dairy — every component in the fluid path must deliver uncompromising...

Understanding Good Manufacturing Practices (GMP) in Sanitary Production

In highly regulated industries like food, beverage, and pharmaceutical production, maintaining quality and consistency is non-negotiable. One of the foundational frameworks supporting...

Rubber Hoses: Flexibility & Reliability for Hygienic Processing

In most hygienic production environments, hoses are the arteries of the process line. Among the many hose styles available, rubber sanitary hoses remain a popular work‑horse option thanks...

Boost Sanitary Efficiency With the Right Washdown Station

When a production line pauses for cleaning, every minute matters. A washdown station, also called a hot-and-cold mixing unit, mixing unit, or blending station gives operators an immediate...

6 Signs That It’s Time to Replace Your Sanitary Valves

In every hygienic processing facility sanitary valves act as gatekeepers of product integrity. Ball valves, butterfly valves, and check valves each play a distinct role, yet the warning...

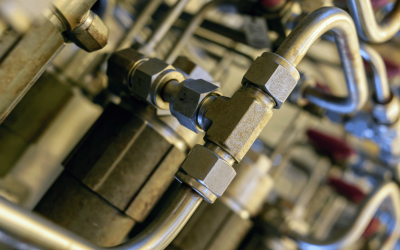

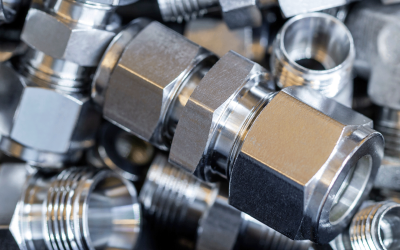

Why Compression Fittings are Gaining Traction for Sanitary Applications

In sanitary processing industries, like food and beverage production or pharmaceutical production, uncompromising hygiene, reliability, and efficiency are the gold standard. When it comes...

Nominal Pore Size in Filtration: What It Means and Why It Matters

In hygienic manufacturing—from food and beverage production and breweries to pharmaceuticals manufacturing—sanitary filtration is more than a matter of quality; it's a non-negotiable...