Sanitary Sample Valves: What They Are, How They Work, and When to Use Them In hygienic processing, representative samples are essential for quality control, release testing, and troubleshooting. Sanitary sample valves are purpose-built to draw those samples safely and repeatably...Read More

Gauges

The role of accuracy in sanitary gauges cannot be overstated when it comes to ensuring product quality in hygienic manufacturing processes. From pressure and temperature to flow, these specialized instruments play a crucial role in maintaining compliance, consistency, and purity throughout production. Investing in high-quality, accurate sanitary gauges is not just a matter of meeting regulatory requirements but a fundamental step towards upholding consumer trust and delivering products of the highest standard.

Categories

Products

Showing 1–12 of 18 resultsSorted by popularity

-

TopLine Sanitary Pressure Gauges

-

Reotemp® Thermoplastic Industrial Process Gauge with 4.5″ Dial (PT45P)

-

Reotemp® Stainless Steel Industrial Process Gauge with 4.5″ Dial (PT45T)

-

Reotemp® Stainless Steel Industrial Fillable Gauge with 2.5″ Dial (PM25C)

-

Reotemp® Stainless Steel Industrial Fillable Gauge with 1.5″ Dial (PM15C)

-

Reotemp® Stainless Steel Industrial Fillable Gauge with 2″ Dial (PM20C)

-

Reotemp® Stainless Steel Heavy Duty Repairable and Fillable Gauge with 4″ Dial (PR40S)

-

Reotemp® Stainless Steel Heavy Duty Repairable and Fillable Gauge with 6″ Dial (PR60S)

-

Reotemp® Low Pressure Gauge with 2.5″ Dial (PC25N)

-

Reotemp® Stainless Steel Low Pressure Gauge with 4″ Dial (PC40S)

-

Reotemp® Stainless Steel Low Pressure Gauge with 2.5″ Dial (PC25S)

-

Reotemp® General Purpose Brass Gauge with 1.5″ Dial (PD15N)

Related Blog Posts

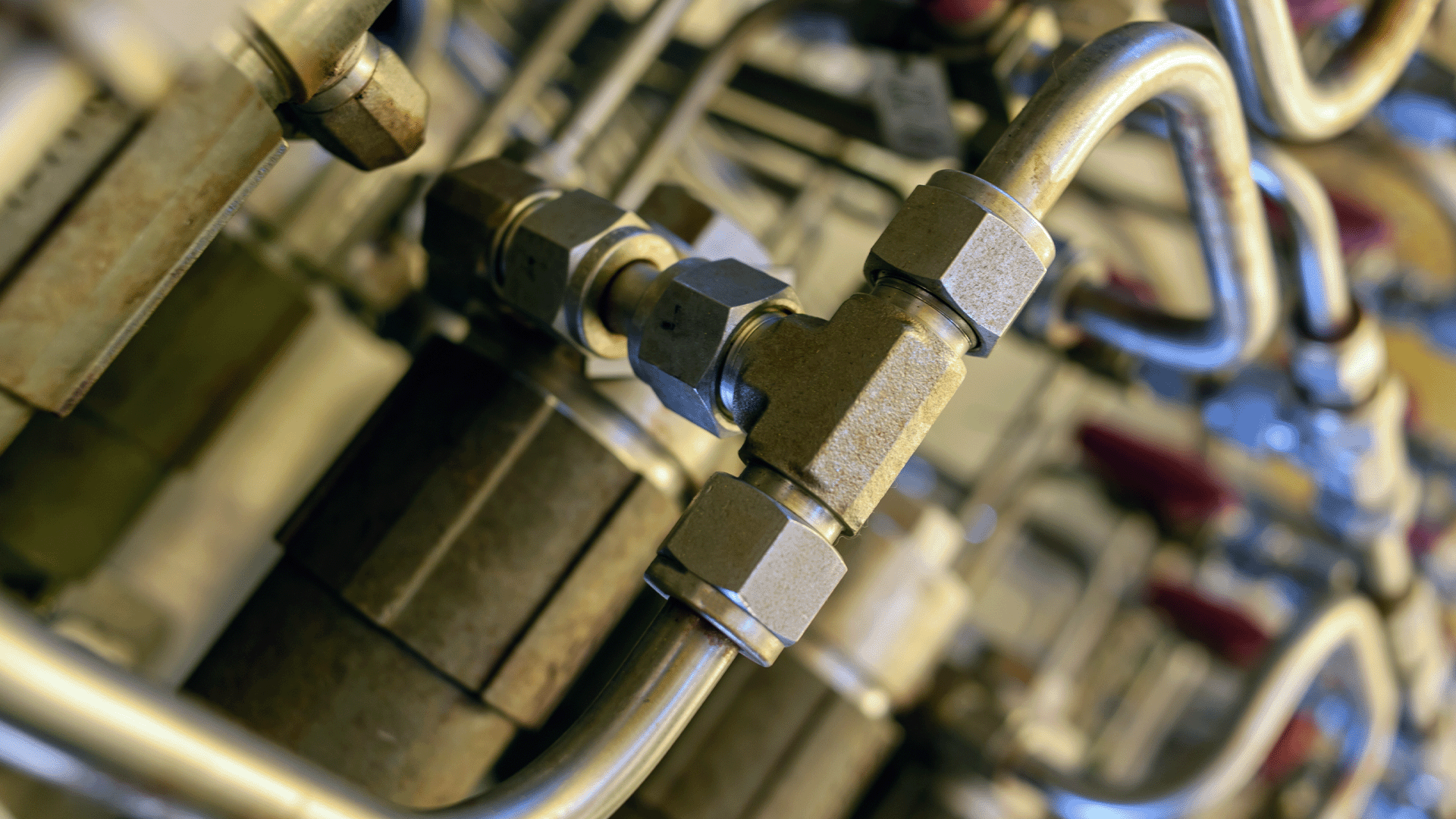

Understanding NPT Pipe Fittings: When and Where to Use Them

Choosing the right type of fitting is important for system integrity, safety, and compliance. One widely used fitting style is the NPT fitting. We’ll cover more about what NPT stands for, when to use NPT fittings, and what industries usually...Read More

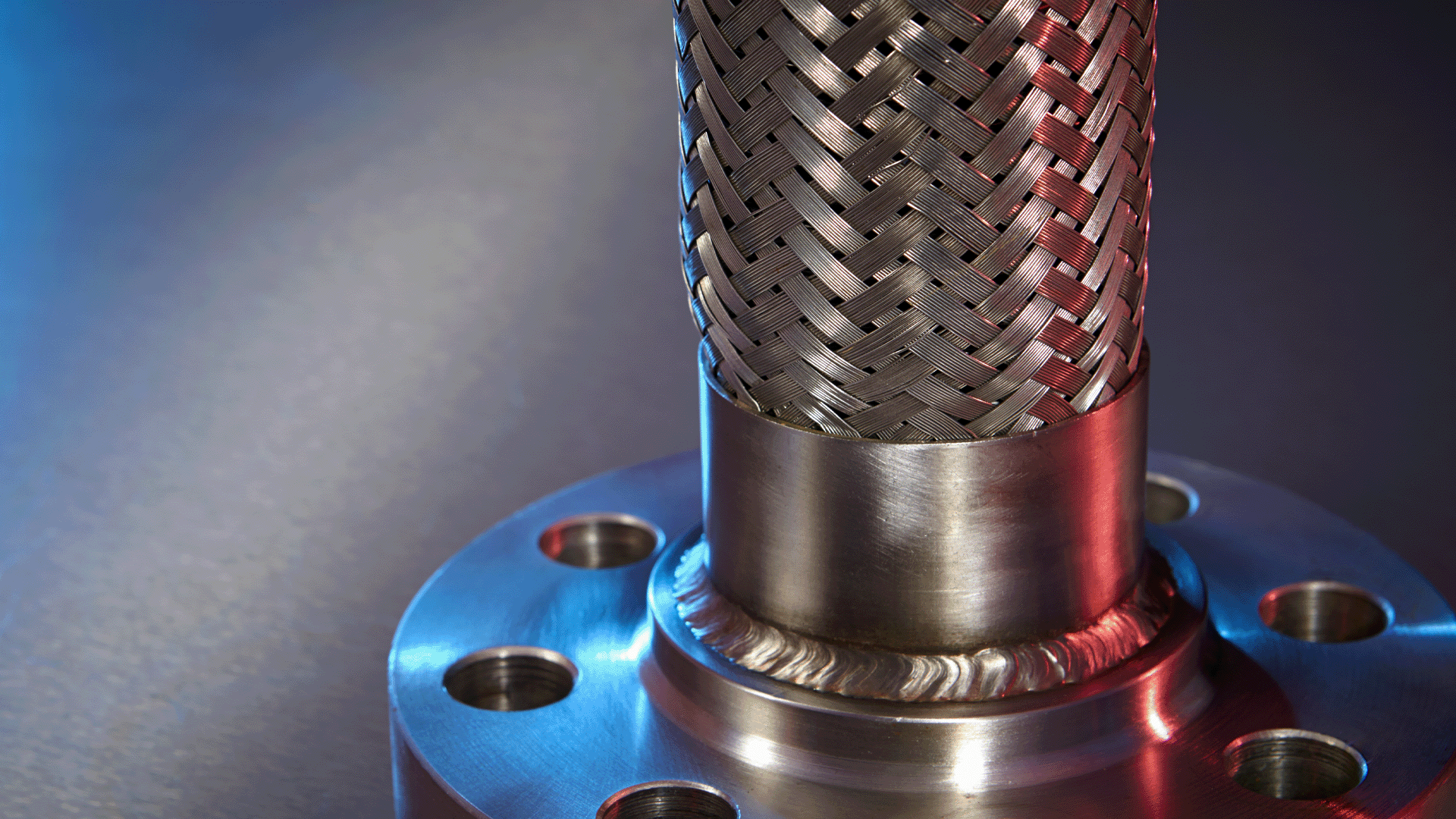

Stainless Steel Braided Hoses: Strength for Sanitary Processing

In hygienic processing environments — whether you’re blending beverages, fermenting biologics, or packaging dairy — every component in the fluid path must deliver uncompromising cleanliness and reliability. A stainless steel braided hose does exactly that: it marries a smooth, cleanable...Read More