3-A Certified Parts for the

Food Processing Industry

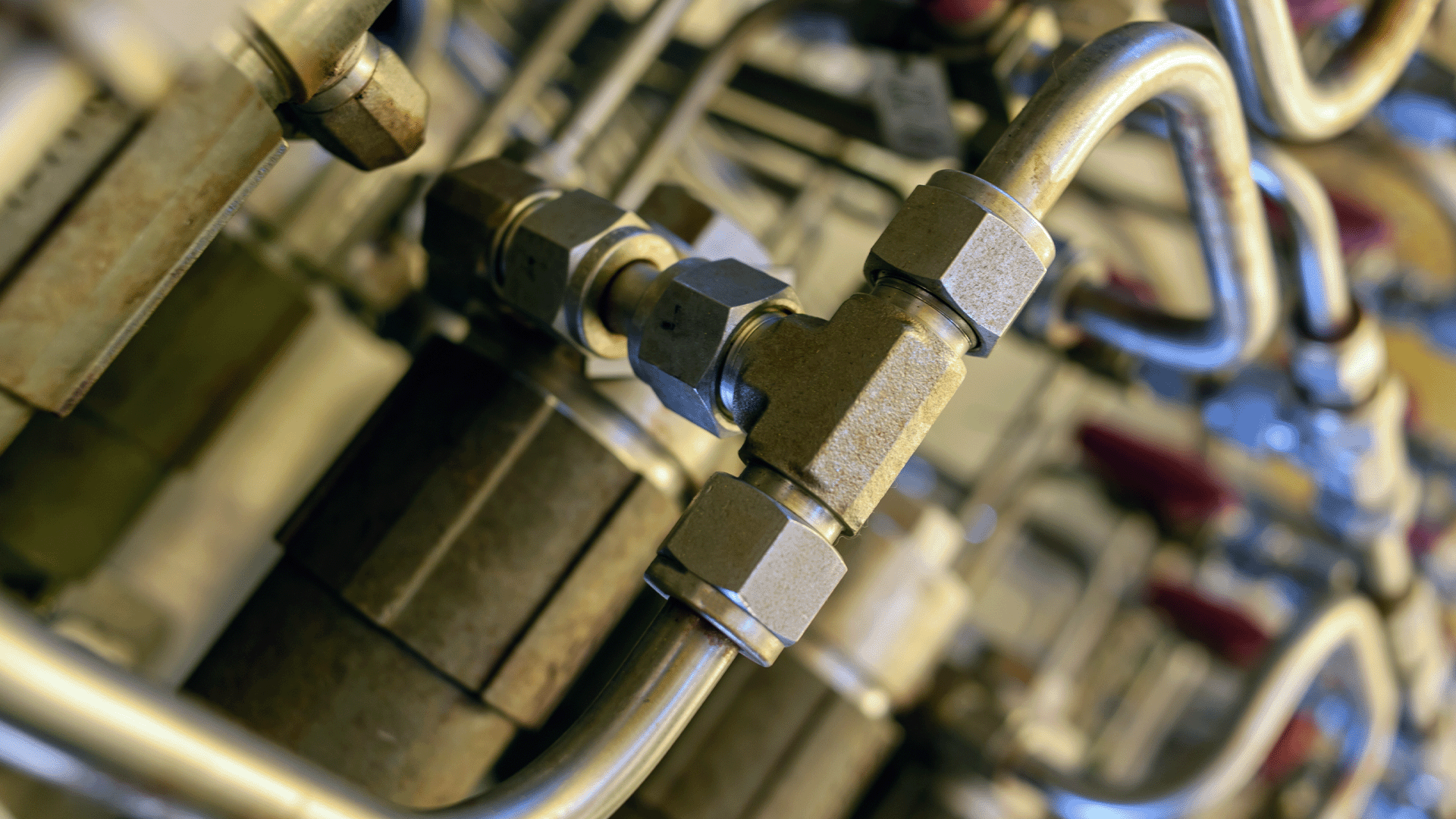

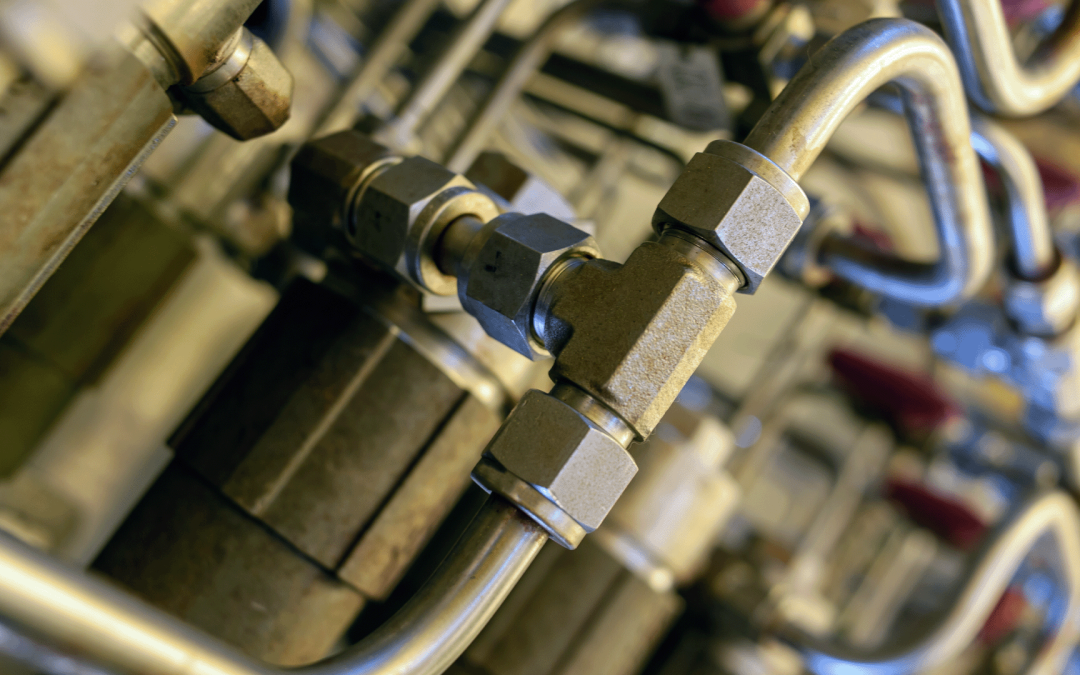

Contaminated production runs don’t just cause downtime, headaches, and lost revenue. They disrupt your entire operation. That’s why food and beverage processors nationwide trust Sanitary Fittings for 3-A certified, food-grade stainless steel fittings, tubing, valves, and more. With our large in-stock selection, fast shipping, and responsive customer service, we make it easy to get the right parts when you need them.

Whether you’re expanding your operation, scheduling annual maintenance, or facing an urgent repair, Sanitary Fittings is your trusted partner for hygienic process solutions.

What are 3-A Sanitary Standards and How Do I Meet Them?

With consumer safety at stake, companies rely on 3-A Sanitary Standards

What Are 3-A Sanitary Standards?

3-A Sanitary Standards were developed as a collaboration between various sectors of the sanitary equipment industry, including regulatory agencies, equipment manufacturers, and end-users. Their goal is to establish comprehensive benchmarks for sanitary design and construction. By meeting 3-A criteria, manufacturers demonstrate that their products are engineered to prevent contamination and promote cleanliness, ultimately safeguarding the integrity of food-grade products.

When it comes to components, like sanitary tubing, 3-A standards ensure that these parts have smooth internal surfaces free from pits or crevices. These surfaces minimize the risk of harboring bacteria and make routine cleaning more efficient. Furthermore, strict welding and polishing protocols, as well as appropriate material selection, are all part of the criteria that ensure long-term hygiene and reliable performance under frequent high-temperature cleanings or sterilization processes.

How Are 3-A Standards Met?

Design and Material Selection

Equipment and parts must be carefully designed so there are no hard-to-reach areas where microorganisms can accumulate. Approved materials, often high-grade stainless steel, are required to withstand rigorous cleaning protocols and resist corrosion. This emphasis on quality materials maintains structural integrity and sanitation over a product’s lifespan.

Surface Finishes

Smooth internal finishes are crucial to prevent microbial buildup. Typically, surfaces should have a roughness average (Ra) within a specified limit. While exact measurements can vary, the principle remains the same: the smoother the surface, the easier it is to sanitize.

Clean-In-Place (CIP) Compatibility

Hygienic processing facilities often use Clean-In-Place (CIP) or Sterilize-In-Place (SIP) systems to streamline cleaning without disassembling equipment. Components meeting 3-A standards are designed to withstand repeated exposure to high temperatures, chemical cleaning agents, and other sterilization procedures.

Regular Inspections and Audits

Maintaining 3-A compliance involves consistent monitoring. Inspections and audits (both internal and external) confirm that equipment remains in top condition and adheres to the latest guidelines.

Shop for Food-Grade Parts

With thousands of products that are 3-A certified, we’ve got everything you need to stay up and running

Fittings & Clamps

Shop our wide range of food-grade stainless steel fittings and connectors to ensure leak-proof connections. Available in both 304 and 316L stainless steel. Most items are manufactured in accordance with 3A standards and are precision engineered for the most demanding environments.

Washdown Stations

We offer both steam and hot water mixing stations designed to enhance your sanitation processes. We also stock all of the necessary washdown system accessories, such as premium sanitary hoses, hose sprayers, hose racks, for all your plant processing needs.

Sanitary Tubing

We source hygienic stainless steel tubing for carrying and distributing food and beverage products. Manufactured to the stringent ASTM A270 S2 specifications, this high-quality tubing is 100% bore-scoped and polished on both the ID and OD to minimize surface anomalies.

Why Choose Sanitary Fittings?

We’ve got the experience in the sanitary industry that sets us apart from typical providers of hygienic equipment

Custom Fabrication Capabilities

Large Selection of Products and Inventory

Same Day Shipping on Most Orders

Exceptional Customer Service

Food Processing FAQs

Common questions about hygienic design, food processing systems, components, and processes

What makes sanitary fittings "food‑grade"?

Our fittings are 3‑A certified and made with non-toxic, corrosion-resistant stainless steel, ensuring surfaces are safe for food contact, easy to clean, and reduce contamination risks.

Learn more about, “What “Food-Grade” Means in Sanitary Processing“.

Why is 3‑A certification important in food processing?

It ensures products meet strict hygienic design standards, your processing line remains safe and easy to clean, and remains compliant.

For more in-depth information, read “3-A Standards and How to Meet Them“.

Do your food‑grade hoses resist high temperatures and sanitizing chemicals?

Yes, most of our hoses are engineered to withstand high temperatures, pressure, and cleaning agents without compromising material integrity or flavor neutrality.

Shop our selection of, “Food-Grade Hoses“.

Are your food-grade fittings compatible with CIP (Clean-in-Place) systems?

Yes. Our stainless steel food-grade fittings are engineered to withstand the high temperatures, pressures, and chemical agents used in CIP and SIP processes. This ensures easy sanitation without needing to dismantle your processing line, helping maintain hygienic integrity and reduce downtime.

Learn more about, “Clean In Place (CIP) Essentials for Manufacturers“.

What grades of stainless steel are available for food-grade fittings?

We offer fittings primarily in 304 and 316L stainless steel. While 304 is commonly used in general food processing applications, 316L provides superior resistance to chlorides, acids, and corrosive environments, which makes it ideal for dairy, sauces, high-salt, or acidic products.

Tune up your knowledge on, “304 vs 316 Stainless Steel“.

How do 3-A sanitary standards affect fitting design and performance?

3-A standards require fittings to be designed with smooth, crevice-free surfaces that prevent product buildup and bacterial growth. This means all contact surfaces are polished to a hygienic finish and built for ease of cleaning, long service life, and compliance with food safety regulations.

Popular Blog Posts

About food processing components, guides, sanitary design, and more

Sanitary Sample Valves: How to Select the Right Valve

Sanitary Sample Valves: What They Are, How They Work, and When to Use Them In hygienic processing, representative samples are essential for quality...

Best Practices for Cleaning and Maintaining Sanitary Sample Valves

Product quality and safety hinge on maintaining your sanitary equipment. Sanitary sample valves that are widely used in the food, beverage, and...

Understanding NPT Pipe Fittings: When and Where to Use Them

Choosing the right type of fitting is important for system integrity, safety, and compliance. One widely used fitting style is the NPT fitting. We'll...

For more information on this topic and more, visit our blog