Sanitary Solutions for the

Industrial Industry

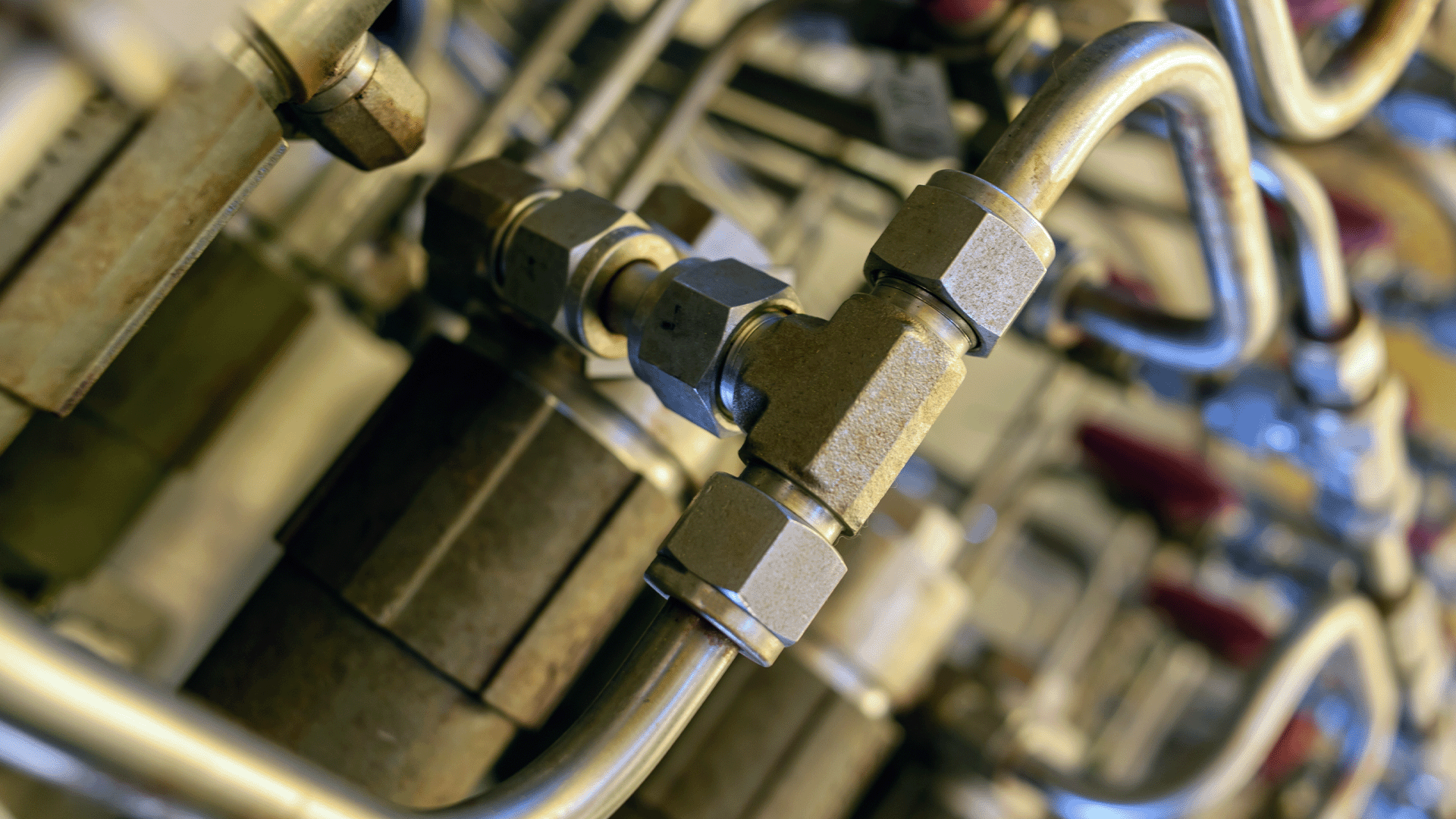

At Sanitary Fittings, we supply premium stainless steel components, from Tri-Clamp fittings and valves to washdown stations and gaskets, all designed for industrial and manufacturing operations that demand uncompromising cleanliness, reliability, and speed. Our 304 and 316 stainless steel products resist corrosion and streamline sanitation, making them ideal for food processing lines, cooling systems, and high-pressure equipment.

Whether you’re handling routine maintenance, tackling unplanned repairs, or upgrading your facility, Sanitary Fittings is your trusted partner for hygienic process solutions that keep your operation running smoothly.

Custom Manufactured vs. Off-the-Shelf Parts

5 key decisions to determine what components you need for your manufacturing facility

Make the Right Choice for Your Manufacturing Facility

When expanding an existing manufacturing layout or building a new plant, one of the key decisions you’ll face is whether to opt for custom-manufactured parts or off-the-shelf components. This choice can significantly impact your project’s timeline, budget, and overall efficiency. Understanding when to choose one over the other is essential for optimizing your operations and achieving long-term success.

1. Understanding Off-the-Shelf Parts: Pros and Cons

Off-the-shelf parts are pre-designed, standardized components that are readily available for purchase. These parts are often mass-produced, making them a quick and cost-effective solution for many manufacturing needs.

Pros:

- Cost-Effective: Off-the-shelf parts are usually less expensive because they are produced in large quantities.

- Quick Availability: Since these parts are readily available, lead times are typically shorter, which can help accelerate project timelines.

- Reliability: These parts have been tested and used in various applications, so their performance is generally predictable and reliable.

- Standardization: Using standardized parts can simplify maintenance, repairs, and future expansions.

Cons:

- Limited Customization: Off-the-shelf parts may not perfectly fit your specific needs, leading to potential compromises in performance or efficiency.

- Compatibility Issues: These parts may not integrate seamlessly with your existing equipment or layout, requiring additional modifications or adjustments.

2. When to Choose Off-the-Shelf Parts

- Tight Deadlines: If your project timeline is tight, off-the-shelf parts can help you move quickly and avoid delays.

- Standard Applications: For processes and equipment that don’t require specialized features or unique specifications, off-the-shelf parts are often the best choice.

- Budget Constraints: If you’re working within a limited budget, these parts can offer a cost-effective solution without sacrificing quality.

- Established Systems: When expanding an existing layout with standardized equipment, using off-the-shelf parts ensures consistency and compatibility.

3. Understanding Custom-Manufactured Parts: Pros and Cons

Custom-manufactured parts are designed and produced to meet specific requirements, tailored to your unique manufacturing needs. These parts offer greater flexibility and precision but come with their own set of challenges. Sanitary Fittings is happy to offer a custom manufacturing.

Pros:

- Tailored Solutions: Custom parts are designed to meet your exact specifications, ensuring optimal performance and efficiency.

- Flexibility: You have the freedom to design parts that fit perfectly with your existing equipment or layout, reducing the need for modifications.

- Innovative Features: Custom manufacturing allows you to incorporate innovative features that can give you a competitive edge.

- Long-Term Value: While the upfront cost may be higher, custom parts can offer long-term savings by improving productivity and reducing downtime.

Cons:

- Higher Costs: Custom parts typically come with higher design and manufacturing costs.

- Longer Lead Times: The design, prototyping, and production process for custom parts can be time-consuming, potentially delaying your project.

- Risk of Design Flaws: Since custom parts are unique, there’s a higher risk of encountering design or manufacturing issues that require additional revisions.

4. When to Choose Custom-Manufactured Parts

- Unique Requirements: If your project involves specialized processes, unique layouts, or innovative technology, custom parts may be necessary to meet your exact needs.

- Integration Needs: When integrating new equipment with existing systems, custom parts can ensure seamless compatibility and optimal performance.

- Long-Term Vision: If you’re looking to future-proof your operations with advanced features or innovative designs, custom manufacturing can be a strategic investment.

- High-Value Production: For high-value or precision-critical applications, custom parts can provide the reliability and accuracy needed to maintain quality standards.

5. Striking the Right Balance

In many cases, the best approach is a combination of both custom-manufactured and off-the-shelf parts. By carefully assessing your project’s needs, you can determine where customization is necessary and where standardization can save time and money.

Key Considerations:

- Project Scope: Evaluate the scale and complexity of your project to identify areas where custom solutions will add value.

- Budget and Timeline: Balance your budget constraints with your project timeline to make informed decisions about where to invest in custom parts.

- Long-Term Goals: Consider your long-term operational goals and how each option will impact your plant’s efficiency, scalability, and maintenance needs.

Shop Popular Sanitary Parts

Thousands of in-stock products to keep your facility up and running with free shipping on orders over $100

Fittings & Clamps

Shop our wide range of food-grade stainless steel fittings and connectors to ensure leak-proof connections. Available in both 304 and 316L stainless steel. Most items are manufactured in accordance with 3A standards and are precision engineered for the most demanding environments.

Washdown Stations

We offer both steam and hot water mixing stations designed to enhance your sanitation processes. We also stock all of the necessary washdown system accessories, such as premium sanitary hoses, hose sprayers, hose racks, for all your plant processing needs.

Sanitary Tubing

We source hygienic stainless steel tubing for carrying and distributing food and beverage products. Manufactured to the stringent ASTM A270 S2 specifications, this high-quality tubing is 100% bore-scoped and polished on both the ID and OD to minimize surface anomalies.

Why Choose Sanitary Fittings?

We’ve got the experience in the sanitary industry that sets us apart from typical providers of hygienic equipment

Custom Fabrication Capabilities

Large Selection of Products and Inventory

Same Day Shipping on Most Orders

Exceptional Customer Service

Related FAQs

Common questions about hygienic design, manufacturing systems, components, and processes

What makes sanitary fittings ideal for industrial and manufacturing use?

Do you provide fittings for small repairs and large facility upgrades?

Yes. With no minimum order requirements, Sanitary Fittings supports everything from single-part emergency repairs to full facility overhauls. Whether it’s one gasket or an entire system of valves and hoses, we have you covered.

Do your food‑grade hoses resist high temperatures and sanitizing chemicals?

Yes, most of our hoses are engineered to withstand high temperatures, pressure, and cleaning agents without compromising material integrity or flavor neutrality.

Shop our selection of, “Food-Grade Hoses“.

Are your fittings compatible with CIP (Clean-in-Place) systems?

Yes. Our stainless steel fittings are engineered to withstand the high temperatures, pressures, and chemical agents used in CIP and SIP processes. This ensures easy sanitation without needing to dismantle your processing line, helping maintain hygienic integrity and reduce downtime.

Learn more about, “Clean In Place (CIP) Essentials for Manufacturers“.

What’s the difference between 304 and 316 stainless steel and which should I choose?

We offer fittings primarily in 304 and 316L stainless steel. While 304 is commonly used in general food processing applications, 316L provides superior resistance to chlorides, acids, and corrosive environments, which makes it ideal for dairy, sauces, high-salt, or acidic products.

Tune up your knowledge on, “304 vs 316 Stainless Steel“.

How do I start a custom fabrication request?

Our process usually starts out with a request from the customer. While we prefer to have detailed drawings from the customer this isn’t always the case. Sometimes we get rough dimensions and explanations, sometimes we get cocktail napkin sketches, and sometimes we receive just a rough idea of what the customer is trying to accomplish.

Either way, we have a team of engineers and designers available to walk the customer through this process of clearly defining their needs.

Read more about this process, “Custom Manufacturing from Sanitary Fittings“.

Popular Blog Posts

About hygienic components, guides, sanitary design, and more

Sanitary Sample Valves: How to Select the Right Valve

Sanitary Sample Valves: What They Are, How They Work, and When to Use Them In hygienic processing, representative samples are essential for quality...

Best Practices for Cleaning and Maintaining Sanitary Sample Valves

Product quality and safety hinge on maintaining your sanitary equipment. Sanitary sample valves that are widely used in the food, beverage, and...

Best Practices for Cleaning and Maintaining Your Washdown Station Hose

Best Practices for Cleaning and Maintaining Your Washdown Station Hose In any sanitary processing facility, washdown stations and hoses are essential...

For more information on this topic and more, visit our blog