Stainless Steel Components for

Data Center Cooling

With increasing rack densities and the rise of AI workloads in hyperscale and colocation data centers, air cooling isn’t enough to keep equipment cool. Liquid cooling with stainless steel components offers superior heat removal, compatibility with a wide range of coolant types, and higher reliability.

Why is Air Cooling Not Cutting it Anymore?

5 common reasons data centers are making the switch to liquid cooling

Data centers are transitioning from air cooling systems to more efficient liquid cooling solutions. As computing demands grow and server densities increase, air cooling struggles to dissipate the heat generated by high-performance processors. Liquid cooling offers an alternative by directly absorbing and transferring heat away from critical components, resulting in more stable operating temperatures and improved energy efficiency.

This shift away from air cooling not only allows facilities to support higher processing loads in a smaller footprint but also reduces overall energy consumption and environmental impact. With advancements in liquid cooling technology, data centers can achieve greater performance, lower operational costs, and extend the lifespan of equipment, making it a solid choice for the future of high-density computing.

1. Inability to Keep Up with Heat Density

- Modern processors, especially those used in AI and HPC, generate significantly more heat than older generations.

- Air cooling struggles to effectively dissipate this heat in high-density server configurations, where equipment is packed closely together.

- This leads to thermal throttling, where performance is reduced to prevent overheating, and increased energy consumption to maintain adequate cooling.

2. Rising Energy Costs and Sustainability Concerns

- Traditional air conditioning systems are energy-intensive, contributing to high operating costs and a large carbon footprint.

- Data centers are under pressure to reduce energy consumption and meet sustainability goals, making air cooling less appealing.

- Liquid cooling can reduce energy consumption by up to 40% compared to air cooling.

3. Space Limitations

- Air cooling systems require large fans, cooling towers, and extensive ductwork, taking up valuable space within the data center.

- Liquid cooling solutions can be more compact, allowing for denser server configurations and more efficient use of space.

4. Improved Performance and Efficiency

- Liquid cooling can maintain lower and more stable temperatures, enabling processors to operate at their optimal performance levels.

- This leads to faster processing speeds and improved overall system performance.Liquid cooling can also reduce the need for large cooling infrastructure, further enhancing energy efficiency.

- Liquid cooling can also reduce the need for large cooling infrastructure, further enhancing energy efficiency.

5. The Rise of AI and HPC

- The increasing demand for AI and HPC applications is driving the need for more powerful and efficient cooling solutions.

- Liquid cooling is well-suited to meet the unique cooling demands of these workloads.

How Are Legacy Liquid Cooled Data Centers Modernizing?

As data centers continue to evolve, many are transitioning to stainless steel

As liquid cooling quickly becomes the preferred method for managing the heat generated in data centers, many centers are migrating from brass, copper, or other materials to replacing components with stainless steel. Stainless steel has become the material of choice for many liquid cooling system components due to its hygienic properties, excellent corrosion resistance, compatibility with a wide range of coolants, durability, and scalability.

Smooth, Polished Interior

- Sanitary tubing is polished to a fine RA finish, minimizing particulate buildup, biofilm risk, and flow resistance.

Highly Scalable and Flexible

- Tri-clamp fittings offer fast assembly, low maintenance, and easy ad hoc reconfiguration which makes them ideal for skids or modular cooling systems.

- Stainless steel can be fabricated into various shapes and sizes, allowing for customized cooling solutions to fit the specific needs of a data center.

Corrosion Resistance

- Stainless steel, especially grades like 316, is highly resistant to corrosion, even when exposed to water-based coolants and high temperatures. This is crucial for maintaining the integrity and lifespan of the cooling system.

Compatibility with Coolants

- Stainless steel is compatible with a variety of coolants, including water and deionized water, making it a versatile choice for different cooling system designs.

Shop Our Wide-Range of Liquid Cooling Parts

Everything you need from flow control components to liquid cooling fittings to our custom manufacturing capabilities

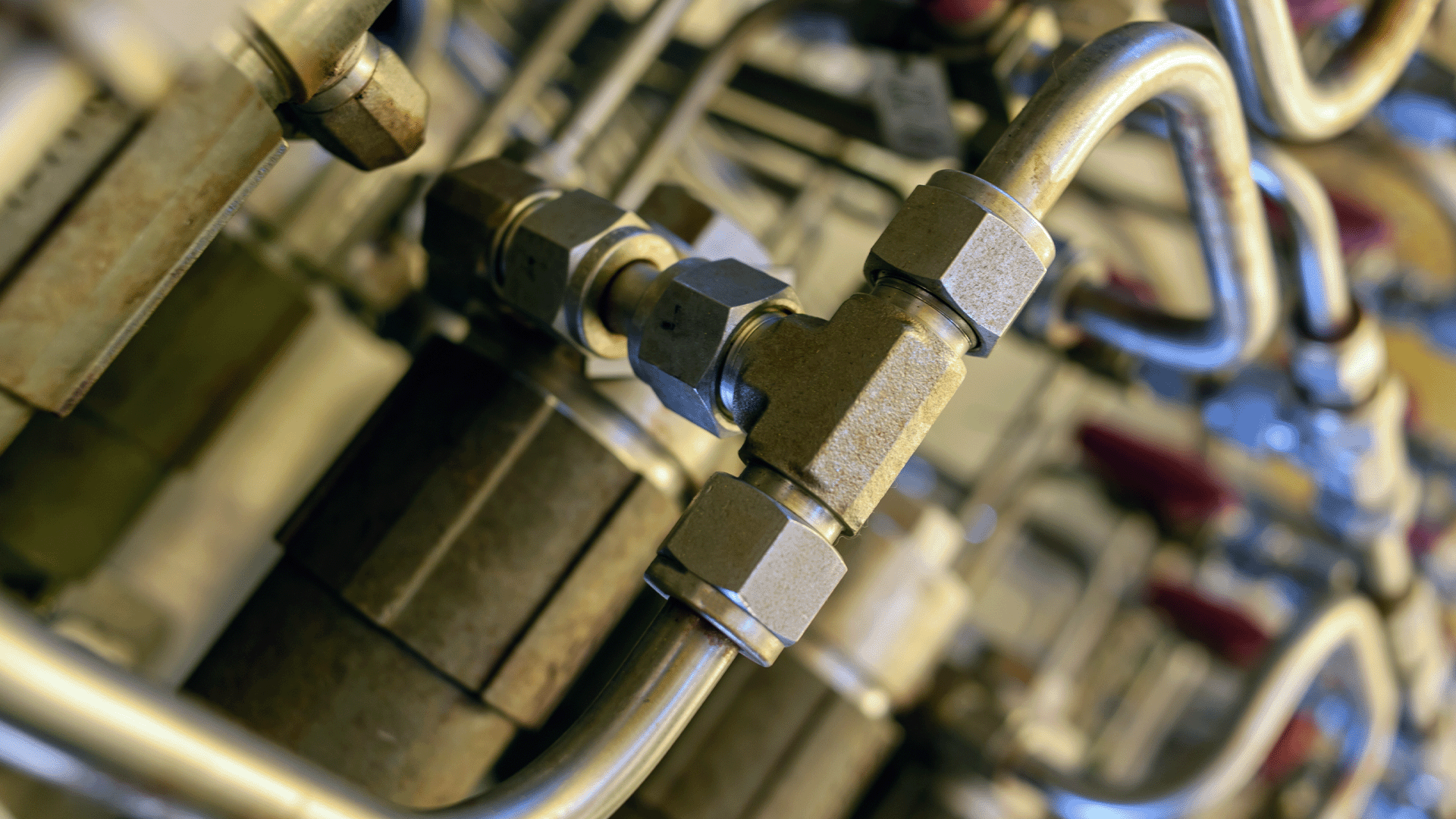

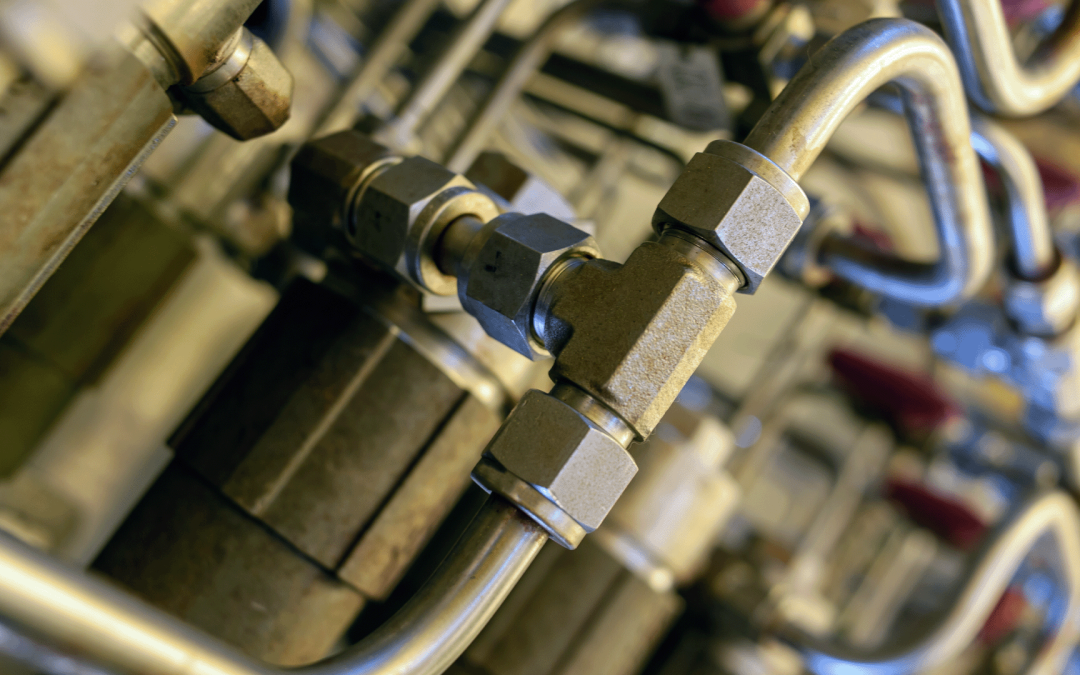

Fittings & Clamps

We carry a wide range of stainless steel fittings and connectors to ensure leak-proof connections with tubing available in both 304 and 316L stainless steel alloy. Most items are manufactured in accordance with 3A standards and are precision engineered to be utilized in the most demanding environments with the ability to withstand high-pressure and high-temperature applications.

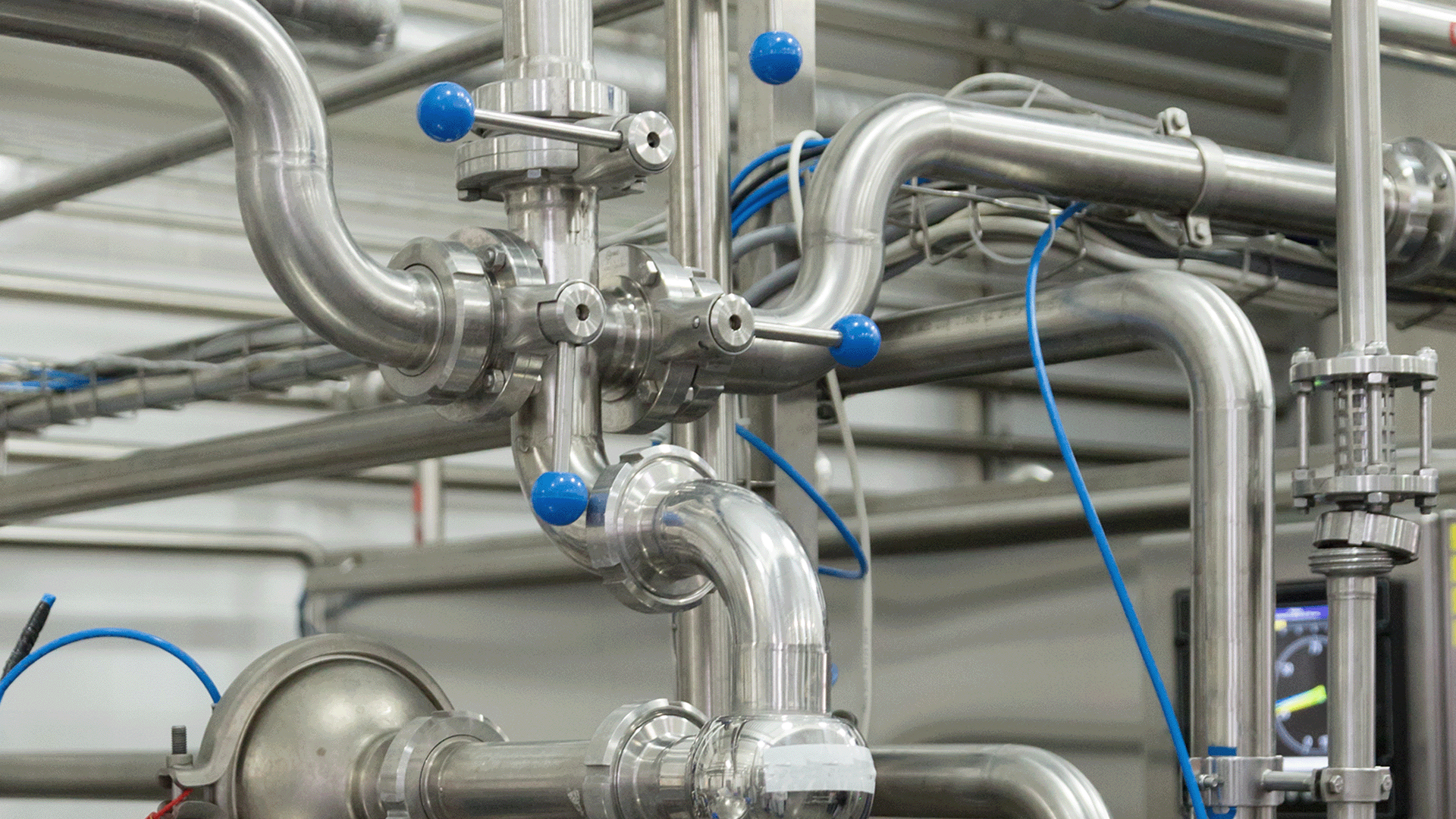

Stainless Steel Valves

These essential components are used to control, direct, and regulate the flow of liquid coolants used in data centers. We a variety of stainless steel valve options designed to meet strict hygiene standards, including ball valves for straightforward on/off control, butterfly valves that pivot a disc for throttling or shutoff, and check valves that allow fluid to flow in one direction and prevent backflow.

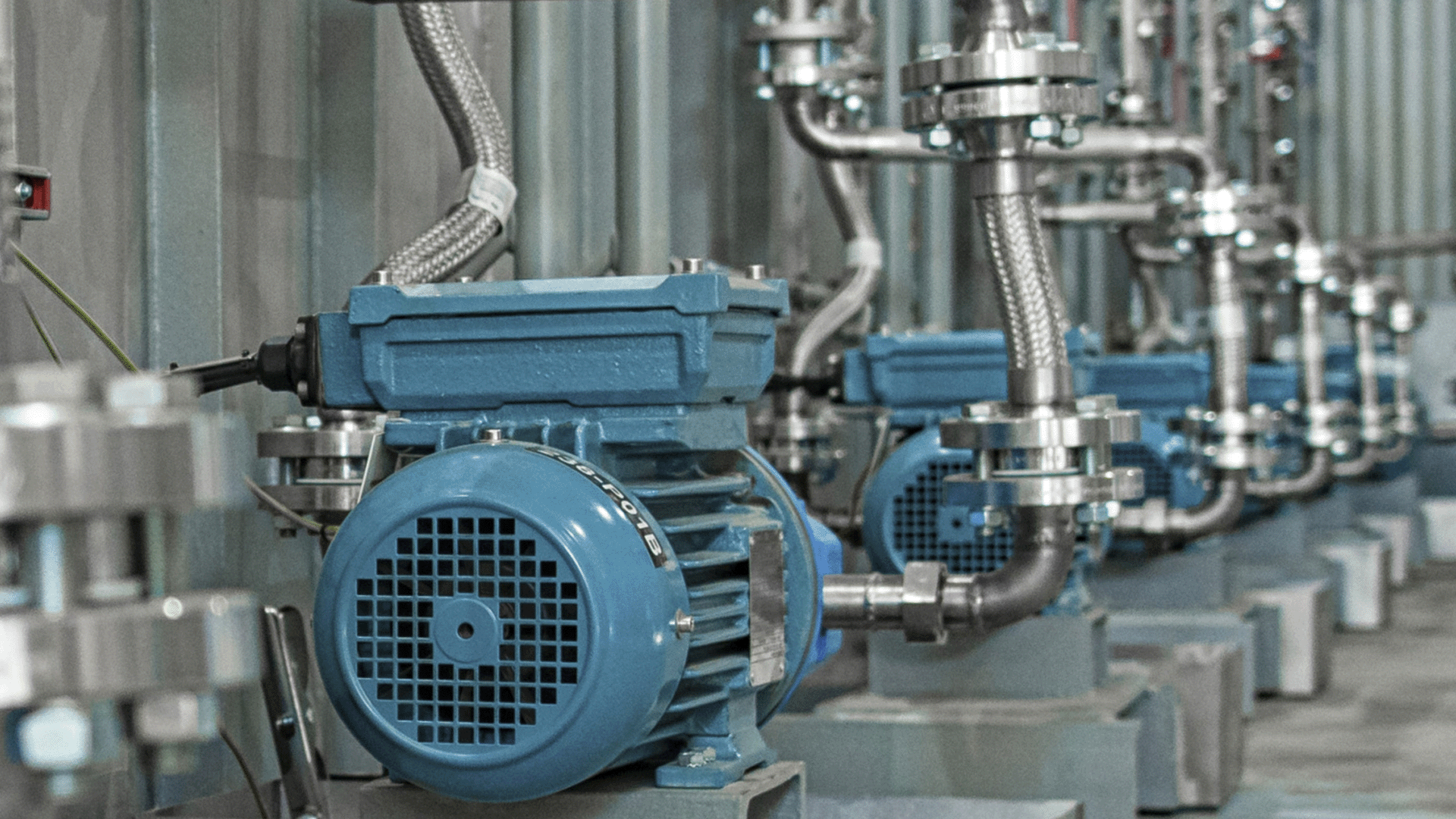

Sanitary Pumps

Sanitary centrifugal pumps are ideal for use in liquid-cooled data centers and are used to circulate a wide range of coolant types throughout the system. As the heart of your liquid cooling operation, trust the TOP-FLO® name to keep your data center operating at peak efficiency. Most Pumps and accessories ship within 1 day with the TOP-FLO® Ready-To-Go program.

Why Choose Sanitary Fittings?

We’ve got the experience in the sanitary industry that sets us apart from typical providers of liquid cooling components

Custom Fabrication Capabilities

Large Selection of Products and Inventory

Same Day Shipping on Most Orders

Exceptional Customer Service

Liquid Cooling FAQs

Common questions about liquid cooling systems, components, and processes

What liquid cooling methods are available?

- Direct-to-chip cooling circulates liquid through cold plates mounted directly on processors, efficiently drawing heat away at the source.

- Immersion cooling submerges entire servers in a non-conductive liquid, providing maximum heat transfer and enabling ultra-high-density deployments.

- Rear-door heat exchangers replace standard rack doors with liquid-cooled panels that capture and dissipate hot exhaust air before it reenters the room.

Depending on the workload and facility design, data centers often adopt one or a combination of these methods to maximize performance, efficiency, and sustainability.

What are the energy costs associated with liquid cooling?

Liquid cooling offers significant efficiency gains for high-density data centers, but it still contributes to overall energy costs. Compared to traditional air cooling, liquid cooling systems typically require less power to move heat away from servers, lowering cooling energy consumption by up to 30–50%. The total cost depends on the design of the components like pumps, heat exchangers, fittings, and pipes.

When optimized, liquid cooling often delivers a lower Power Usage Effectiveness (PUE), making it a cost-effective and sustainable option for facilities running intensive workloads like AI and high-performance computing.

How much water do data centers use and how can usage be reduced?

Water usage in data centers will vary depending on the cooling method and facility size but can range from thousands to millions of gallons per day in large, high-density operations. Traditional evaporative and chiller-based systems consume significant amounts of water, while newer liquid cooling and air-cooled designs can greatly reduce demand.

To minimize usage, some operators are adopting closed-loop systems that recycle water, leveraging free cooling with outside air or shifting to waterless cooling technologies such as immersion and rear-door heat exchangers. These strategies not only lower operating costs but also support sustainability goals by reducing the environmental impact of data center operations.

What are rear-door heat exchangers?

Rear-door heat exchangers are liquid-cooled panels mounted on the back of server racks that capture and remove heat from the exhaust air before it reenters the data hall. By transferring this heat into a circulating liquid loop, they dramatically reduce the need for room cooling and help maintain stable rack temperatures.

This method is especially useful in retrofitting existing facilities since it integrates with standard racks, supports higher server densities, and improves energy efficiency without requiring a complete redesign of the data center’s cooling infrastructure.

Air cooling vs. water cooling: What are the advantages and disadvantages?

Air cooling is the most common method in data centers, offering lower upfront costs and simpler maintenance, but it becomes less efficient as server densities and heat loads increase.

Water cooling (or liquid cooling) is far more effective at removing heat, supporting higher performance systems with reduced energy consumption and improved efficiency. However, it requires greater investment in specialized infrastructure and carries potential risks related to water usage and system complexity.

In short, air cooling is cost-effective for lower-density environments, while water cooling provides superior performance and long-term efficiency for high-demand operations.

What are the advantages of direct-to-chip water cooling?

Direct-to-chip water cooling delivers advantages by circulating liquid directly across cold plates attached to CPUs and GPUs, it removes heat at the source, allowing servers to operate at higher densities and performance levels without overheating.

This targeted approach significantly reduces reliance on traditional air conditioning, lowering overall energy consumption and improving Power Usage Effectiveness (PUE). It also helps extend equipment lifespan by maintaining stable operating temperatures. While it requires specialized infrastructure, direct-to-chip cooling is a scalable, efficient solution for facilities running AI, machine learning, and other compute-intensive workloads.

What is immersion cooling and who uses it?

Immersion cooling is a liquid cooling method where entire servers are submerged in a non-conductive fluid that efficiently absorbs and dissipates heat. This approach eliminates the need for traditional air conditioning, reduces energy costs, and supports ultra-high-density deployments by allowing hardware to run at higher performance levels with greater reliability.

Immersion cooling is increasingly used by hyperscale cloud providers, high-performance computing facilities, and organizations running AI or machine learning workloads. In these industries heat management is critical and efficiency gains translate directly into performance and cost savings.

Popular Blog Posts

About data center cooling, components, methods, and more

Sanitary Sample Valves: How to Select the Right Valve

Sanitary Sample Valves: What They Are, How They Work, and When to Use Them In hygienic processing, representative samples are essential for quality...

Best Practices for Cleaning and Maintaining Sanitary Sample Valves

Product quality and safety hinge on maintaining your sanitary equipment. Sanitary sample valves that are widely used in the food, beverage, and...

Understanding NPT Pipe Fittings: When and Where to Use Them

Choosing the right type of fitting is important for system integrity, safety, and compliance. One widely used fitting style is the NPT fitting. We'll...

For more information on this topic and more, visit our blog