In hygienic processing environments — whether you’re blending beverages, fermenting biologics, or packaging dairy — every component in the fluid path must deliver uncompromising cleanliness and reliability.

A stainless steel braided hose does exactly that: it marries a smooth, cleanable inner core to a rugged 304/316 stainless braid, creating a flexible assembly that stands up to the rigors of production while protecting product integrity. Learn when it’s time to replace your sanitary hoses.

What Is a Stainless Steel Braided Hose?

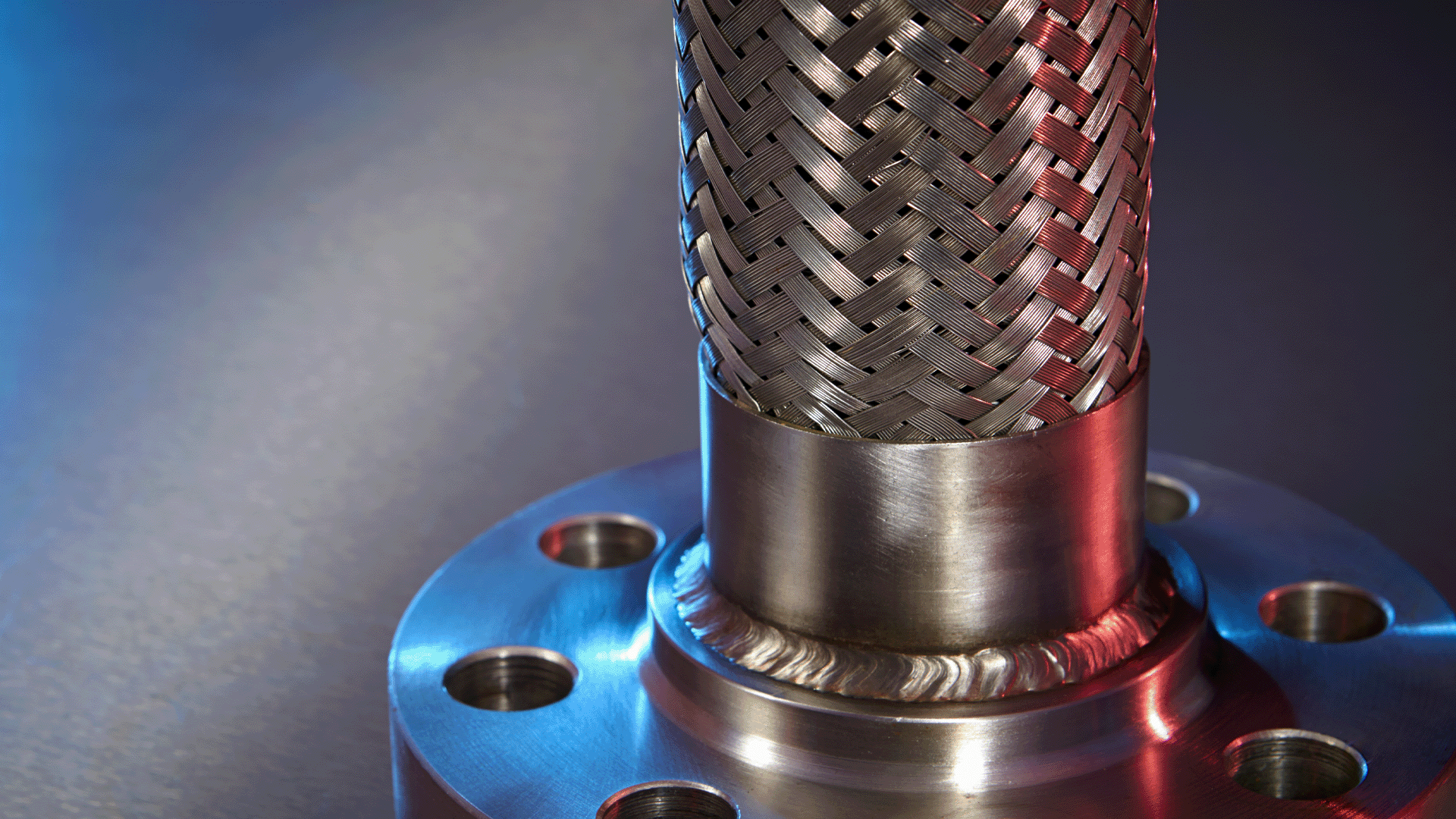

At its core, this hose features a smooth-bore PTFE (polytetrafluoroethylene) or silicone tube that is inert, non‑reactive, and easy to wash down. The tube is then over‑braided with tightly woven stainless steel wire. The braid absorbs pressure, resists kinking, and provides mechanical protection without compromising flexibility. Sanitary end connections, like tri-clamp or compression fittings allow quick integration into existing Clean In Place (CIP) lines.

Industries That Rely on Braided Assemblies

- Food and Beverage: Hot‑fill juice, dairy, brewing, and distilling lines where thermal cycling and pressure spikes are routine.

- Pharmaceutical: High‑purity media transfer under elevated temperatures and aggressive chemical cleaning.

- Cosmetics and Personal Care: Viscous creams or alcohol‑based solutions that demand chemical resistance and contamination control.

- Chemical Processing: Corrosive or solvent‑laden fluids where standard rubber hoses degrade quickly.

Typical Applications in a Sanitary Facility

Braided hoses excel wherever you need a flexible link between rigid stainless piping and vibrating equipment or where frequent change‑overs make hard piping impractical. Common touchpoints include:

- Steam or hot‑water transfer to jacketed kettles

- Load cells on weigh tanks (preventing hard‑pipe stress) – we suggest the Heavy Wall Steel Braided Hose (TSB-H)

- Connections to mobile CIP skids

- High‑pressure pump discharge lines

Benefits

- Pressure and Temperature Resilience: The stainless braid safely contains elevated pressures and withstands temperatures up to 450 °F (232 °C), far beyond most rubber alternatives.

- Chemical Compatibility: PTFE or silicone liners shrug off caustics, solvents, and aggressive cleaning agents.

- Longevity: Heavy‑wall construction reduces fatigue and abrasion, extending service life and lowering total cost of ownership.

- Hygienic Design: Smooth‑bore linings eliminate internal crevices where product could lodge, supporting Good Manufacturing Practices (GMP) compliance and quick CIP cycles.

Drawbacks to Consider

- Weight: The braided layer adds mass, which can strain delicate connectors if unsupported.

- Cost: Upfront pricing is higher than PVC or basic rubber hose, though lifespan often offsets this expense.

- Flex‑Fatigue: Repetitive tight bending can eventually work‑harden the braid; specify proper bend radius and add hose supports where possible.

- Outer‑Braid Cleanability: While stainless is easy to wipe down, the weave can trap soils if hoses are routinely dragged across dusty floors; routine exterior wash‑downs are recommended.

Choosing the Right Assembly

When you evaluate braided hose options, confirm the following:

pressure rating, liner material (PTFE vs silicone), braid alloy (304 vs 316), and compliant certifications (FDA, 3-A, USP Class VI). If you’re unsure, our team can specify an assembly tailored to your operating pressure, temperature, and/or cleaning regimen.

Next Steps

Ready to buy a new hose or replace an existing hose? Explore our full lineup of stainless steel braided hoses or browse our complete sanitary hose catalog.

Explore Our Hose Customization Tool

We understand that every facility’s needs are unique and that you may need a custom hose that is not offered, “off-the-shelf”. In addition to our stainless steel sanitary hoses, we offer a Sanitary Hose Customization Tool that empowers you to create a hose tailored to your exact specifications. Choose your preferred end connections, hose style, diameter, and length to ensure the best possible performance for your operation.