Food-Grade Components for the

Brewing Industry

We’re passionate about brewing! That’s why our brewery-specific components like hoses, pumps, and gaskets are popular for crafting the perfect beer. Products meet rigorous 3A, USDA, and FDA sanitary standards to simplify sanitation, inspection, and swap‑overs between batches. Whether you’re optimizing your brewhouse or scaling up production, our large selection of brewing parts help keep your operation flowing smoothly.

Proud Supporting Member

Sanitary Fittings is a supporting member of the following brewery guilds and associations

What Parts Are Needed to Set Up or Expand My Brewery?

The 4 most important sanitary components for breweries

When setting up or scaling a brewery, you’ll need sanitary fittings, hoses, valves, and pumps that can handle both hot wort transfer and cold-side fermentation without risking contamination. The most common solutions include tri-clamp fittings for quick cleaning and batch changes, FDA-approved brewery hoses for safe transfer of hot and cold liquids, sanitary butterfly or ball valves for precise flow control, and stainless steel pumps designed for brewing applications.

At Sanitary Fittings, we provide all of these components, certified to 3-A, USDA, and FDA standards, so you can source everything you need from one trusted supplier.

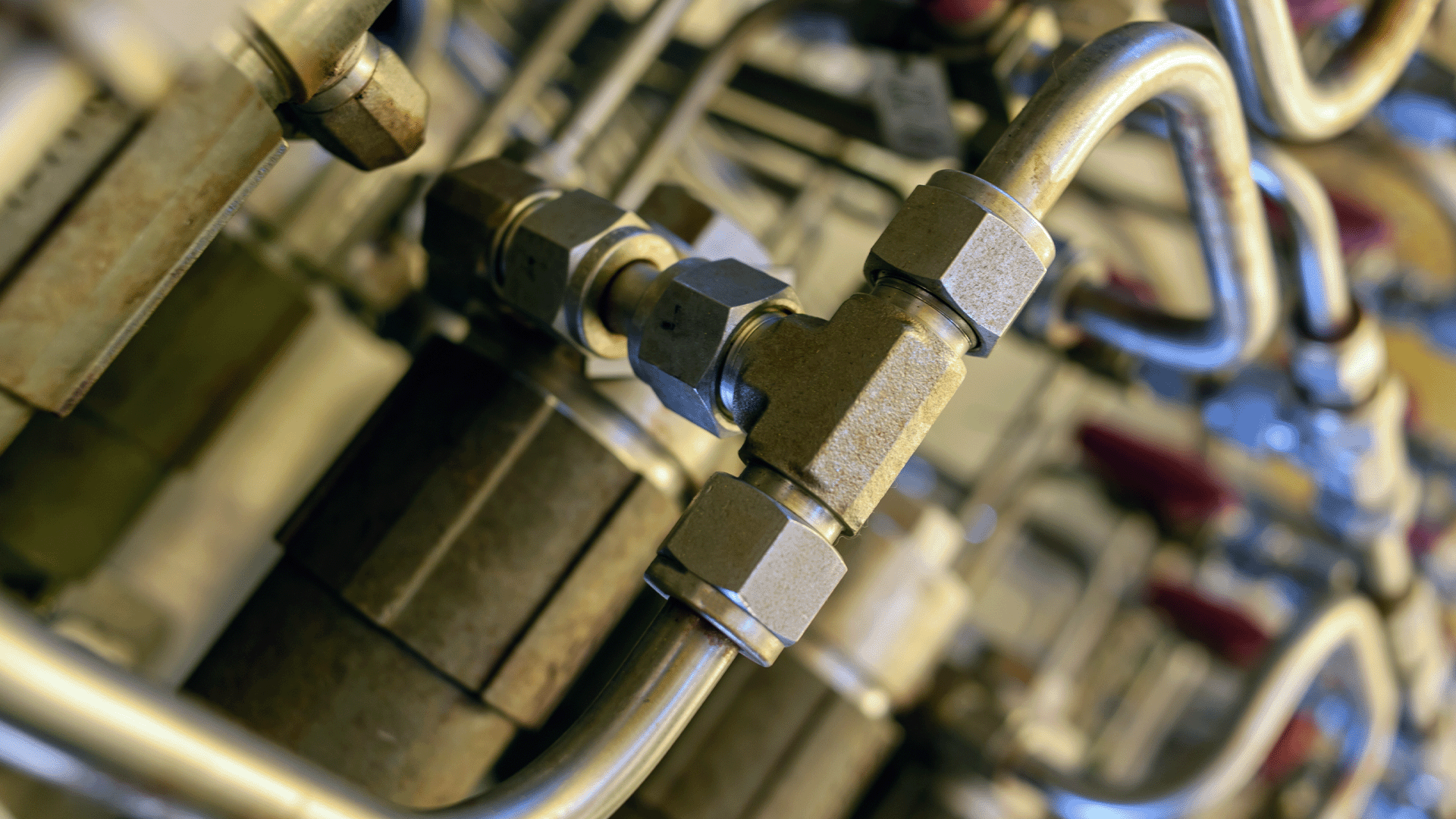

Tri-Clamp Fittings

Tri-clamp fittings are the gold standard in breweries because they’re easy to assemble, disassemble, and clean, making them ideal for frequent batch changes and sanitation. Crafted from polished stainless steel, they ensure a secure, leak-free connection every time.

Food Safe Brewery Hoses

Our brewery hoses are FDA-approved and designed to handle both hot wort and cold-side transfer, offering flexibility without compromising durability. They resist kinking and maintain a smooth interior surface to reduce contamination risk.

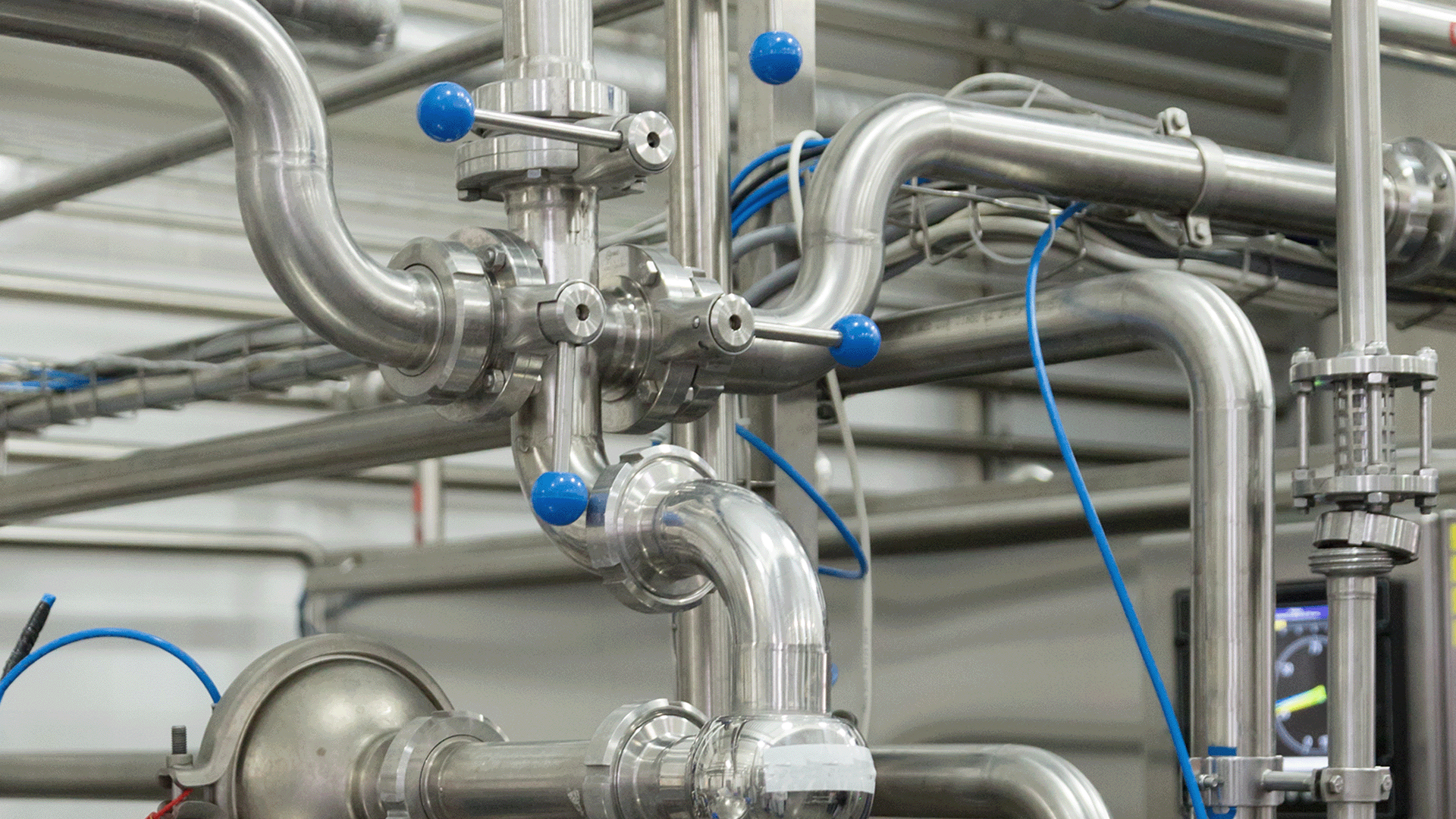

Sanitary Valves (Butterfly & Ball)

Sanitary butterfly and ball valves provide precise flow control while being simple to operate and maintain. Their crevice-free, stainless steel construction ensures clean-in-place (CIP) compatibility and long-lasting reliability.

Learn more about, “Clean In Place (CIP) Essentials for Manufacturers“.

Centrifugal Pumps

Brewery pumps are built to safely transfer liquids at different stages of brewing, from hot wort circulation to cold-side fermentation. Designed for efficiency and sanitation, they help streamline production while protecting flavor integrity.

Deciding on a pump for your brewery is an important decision, “Sanitary Centrifugal Pumps: 3 Basic Facts You Should Know“.

Shop for Brewing Components

Connection options from Tri-Clamp to Camlock and DIN to NPT. We’ve got the right fit for your facility

Fittings & Clamps

Shop our wide range of stainless steel fittings and connectors to ensure leak-proof connections with tubing, available in both 304 and 316L stainless steel. Most items are manufactured in accordance with 3A standards and are precision engineered for the most demanding environments.

Stainless Steel Valves

NPT, Tri-Clamp, DIN, and more stainless steel valve styles that are designed to meet strict hygiene standards, including ball valves for straightforward on/off control, butterfly valves that pivot a disc for throttling or shutoff, and check valves that allow fluid to flow in one direction and prevent backflow.

Sanitary Tubing

We source hygienic stainless steel tubing for carrying and distributing food and beverage products. Manufactured to the stringent ASTM A270 S2 specifications, this high-quality tubing is 100% bore-scoped and polished on both the ID and OD to minimize surface anomalies.

Why Choose Sanitary Fittings?

We’ve got the experience in the sanitary industry that sets us apart from typical providers of brewery equipment

Custom Fabrication Capabilities

Large Selection of Products and Inventory

Same Day Shipping on Most Orders

Exceptional Customer Service

Brewery FAQs

Common questions about brewing systems, components, and processes

What types of sanitary fittings are most commonly used in breweries?

Breweries primarily use Tri-Clamp fittings, along with hose barbs, DIN fittings, and sanitary valves. Tri-clamps are popular because they’re easy to install, remove, and clean which makes them ideal for systems that may require frequent maintenance or batch changeovers.

More questions about the Tri-Clamp style? Read our mini-FAQ, “Tri-Clamp Fittings Frequently Asked Questions (FAQ)“.

Are your fittings certified for use in food and beverage applications?

Yes. All our brewery fittings are 3-A, USDA, and FDA-compliant. This ensures that they meet the highest sanitary standards required in the brewing industry. This certification helps breweries maintain product quality, consistency, and safety.

Learn more about 3-A standards, “What are 3-A Sanitary Standards and How to Meet Them“.

How do I know which fitting size I need for my brewing system?

Fitting sizes are typically based on the outside diameter (OD) of the tubing or piping used in your brewhouse. Our product listings include detailed size charts, and our support team is always available to help you select the right size for your setup.

Learn more, “How to Measure Sanitary Fitting Dimensions“.

Can I use the same fittings for hot wort and cold-side processes?

Yes. Our stainless steel fittings are built to handle the full range of brewing temperatures, from boiling wort to cold-side fermentation. Using high-quality sanitary fittings ensures smooth transfer without leaks or contamination.

Do you offer fittings compatible with European DIN standards?

Absolutely. In addition to tri-clamp fittings, we carry a full line of DIN fittings widely used in European breweries. This ensures compatibility whether you’re sourcing equipment internationally or expanding your current brewhouse.

Get a refresher on DIN Standards, “What is DIN 32676?“.

What type of hose material do I need in my brewery?

Brewery hoses touch many parts of the brewing process, from transferring between tanks, to cleaning and even distribution systems. However, there is rarely one type of hose material that meets all the needs of today’s breweries. What might work great for one application may not be the best selection for another.

Here are the “Common types of hose materials used for brewing“.

Popular Blog Posts

About breweries, brewing components, guides, and more

When to Replace Sanitary Gaskets in Your Manufacturing Facility

In the intricate machinery and processes of manufacturing facilities, even the smallest components play crucial roles in ensuring efficiency and safety....

Best Practices for Cleaning and Maintaining Sanitary Sample Valves

Product quality and safety hinge on maintaining your sanitary equipment. Sanitary sample valves that are widely used in the food, beverage, and...

Understanding NPT Pipe Fittings: When and Where to Use Them

Choosing the right type of fitting is important for system integrity, safety, and compliance. One widely used fitting style is the NPT fitting. We'll...

For more information on this topic and more, visit our blog