3-A Certified Components for the

Winemaking Industry

Great wine depends on more than just grapes: it relies on keeping every transfer clean, consistent, and true to flavor. That’s why wine makers are using 3-A, USDA, FDA compliant transfer hoses, stainless steel clamps, and hygienic valves, to prevent contamination, protect delicate aromas, and maintain the integrity of every batch from crush to bottling.

At Sanitary Fittings, we supply the sanitary fittings and winery hoses that help winemakers reduce downtime and ensure every pour meets the highest standard of quality.

Why Wineries Use Sanitary Fittings for QA

The 4 most importance reasons to use sanitary fittings in winemaking

Wineries have long been associated with craftsmanship, tradition, and the art of producing exquisite wines. In recent years, there has been a growing emphasis on quality assurance and hygiene standards within the wine industry. One crucial aspect that has gained significant attention is the implementation of sanitary fittings.

These fittings play a pivotal role in ensuring the cleanliness and safety of winemaking processes, ultimately contributing to the overall quality of the wines produced.

1. Maintaining Cleanliness and Hygiene

Winemaking involves a delicate balance of science and art. To produce wines of exceptional quality, wineries must prioritize cleanliness and hygiene throughout the production process. Sanitary fittings, also known as hygienic fittings, are specifically designed to meet the stringent requirements of the wine industry.

One of the primary benefits of sanitary fittings is their ability to prevent contamination and microbial growth. They are typically made from materials that are resistant to corrosion, ensuring they do not react with the wine or compromise its quality. Additionally, these fittings are designed with smooth surfaces, minimizing the risk of bacteria or other microorganisms clinging to them.

2. Improving Process Efficiency

Sanitary fittings not only contribute to maintaining cleanliness and hygiene but also improve process efficiency within wineries. These fittings are designed for easy installation, disassembly, and cleaning. The standardized connection systems ensure that fittings can be quickly replaced or modified without disrupting the production flow.

Furthermore, the smooth interior surfaces of sanitary fittings reduce the likelihood of clogs or blockages, enabling a smooth flow of wine during various stages of production. This improves the overall efficiency of winemaking processes, leading to increased productivity and reduced downtime.

3. Versatility and Customization

Wineries come in various sizes and have unique production requirements. Sanitary fittings offer a wide range of options, allowing wineries to customize their setups based on their specific needs. Whether it’s stainless steel valves, clamps, hoses, or gaskets, winemakers can choose fittings that seamlessly integrate with their existing equipment and infrastructure.

The versatility of sanitary fittings extends beyond their compatibility. They can be adapted to accommodate various winemaking techniques, such as different fermentation processes or aging methods. This adaptability ensures that winemakers can experiment and innovate while maintaining the highest standards of cleanliness and hygiene.

4. Compliance with Regulatory Standards

The wine industry is subject to strict regulations and standards to ensure the safety and integrity of the final product. Sanitary fittings play a vital role in helping wineries meet these requirements. By implementing hygienic fittings, wineries can demonstrate their commitment to producing wines that meet the highest sanitary standards.

Adhering to regulatory guidelines not only ensures consumer safety but also enhances the reputation of wineries. Consumers are increasingly aware and concerned about the quality and safety of the products they consume. Wineries that prioritize cleanliness and hygiene through the use of sanitary fittings can build trust and loyalty among consumers.

Shop Winery Hoses and More

From winery transfer hoses to FDA-approved fittings, we have it all

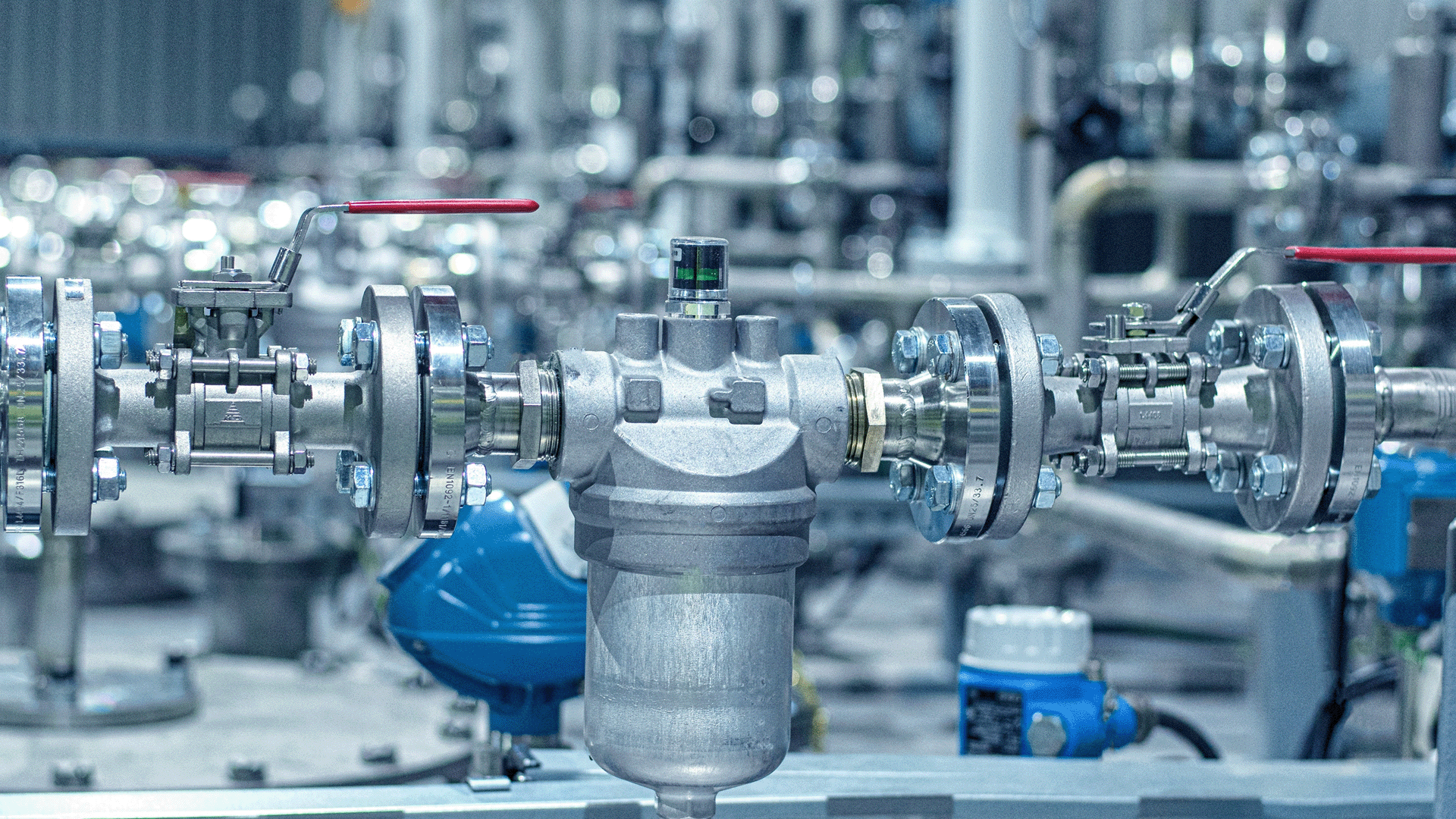

3-A Stainless Fittings

We offer both 304 and 316L stainless steel alloy in sizes from 1” to 12”. Manufactured in accordance with 3A standards, these items are precision engineered to be utilized in the most demanding environments of the wine making industry.

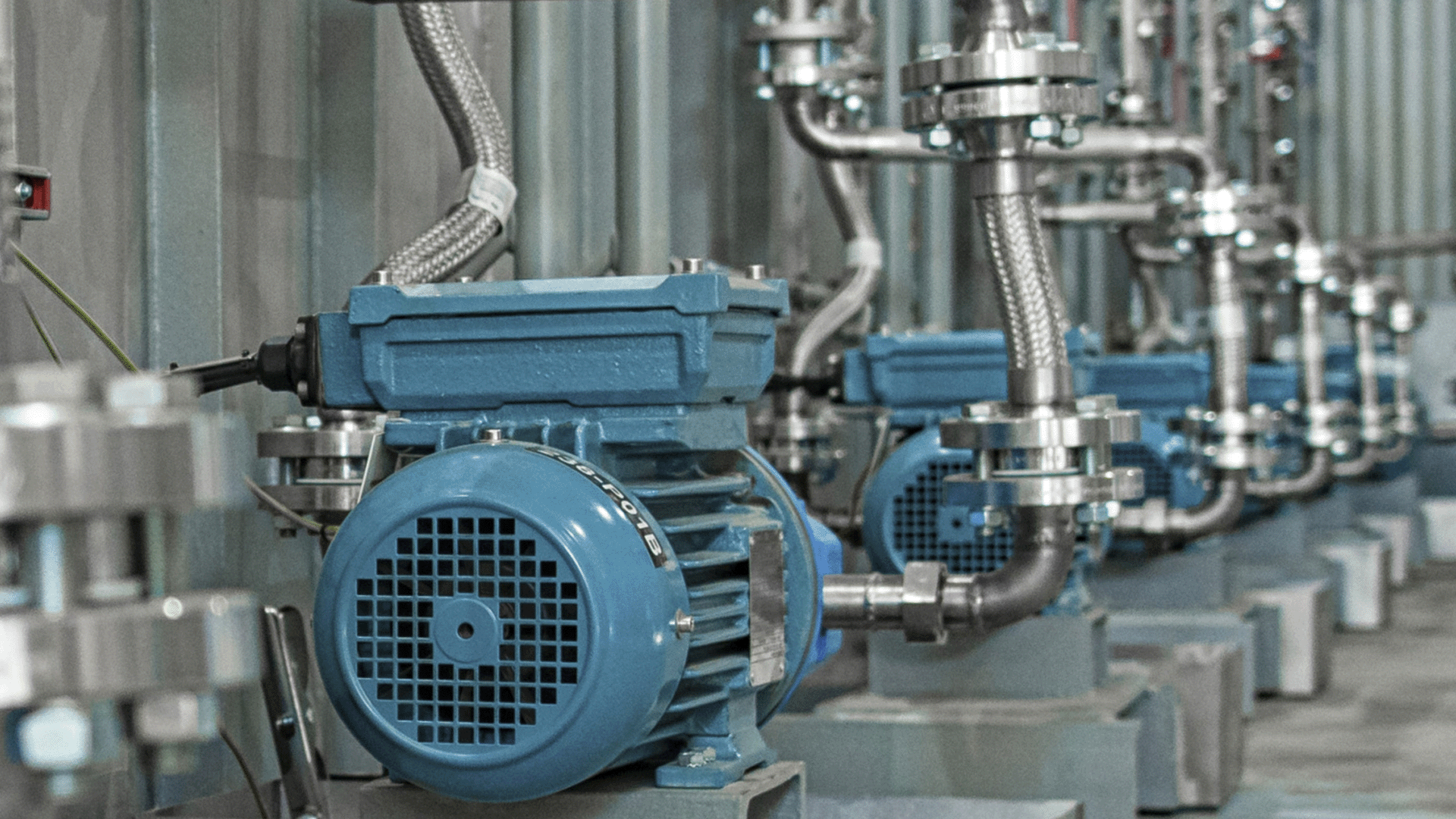

Centrifugal Pumps

Sanitary centrifugal pumps are ideal for use in most process applications in the winemaking, food, and other sanitary process industries. TOP-FLO® pumps are suitable for use in CIP (clean-in-place) installations.

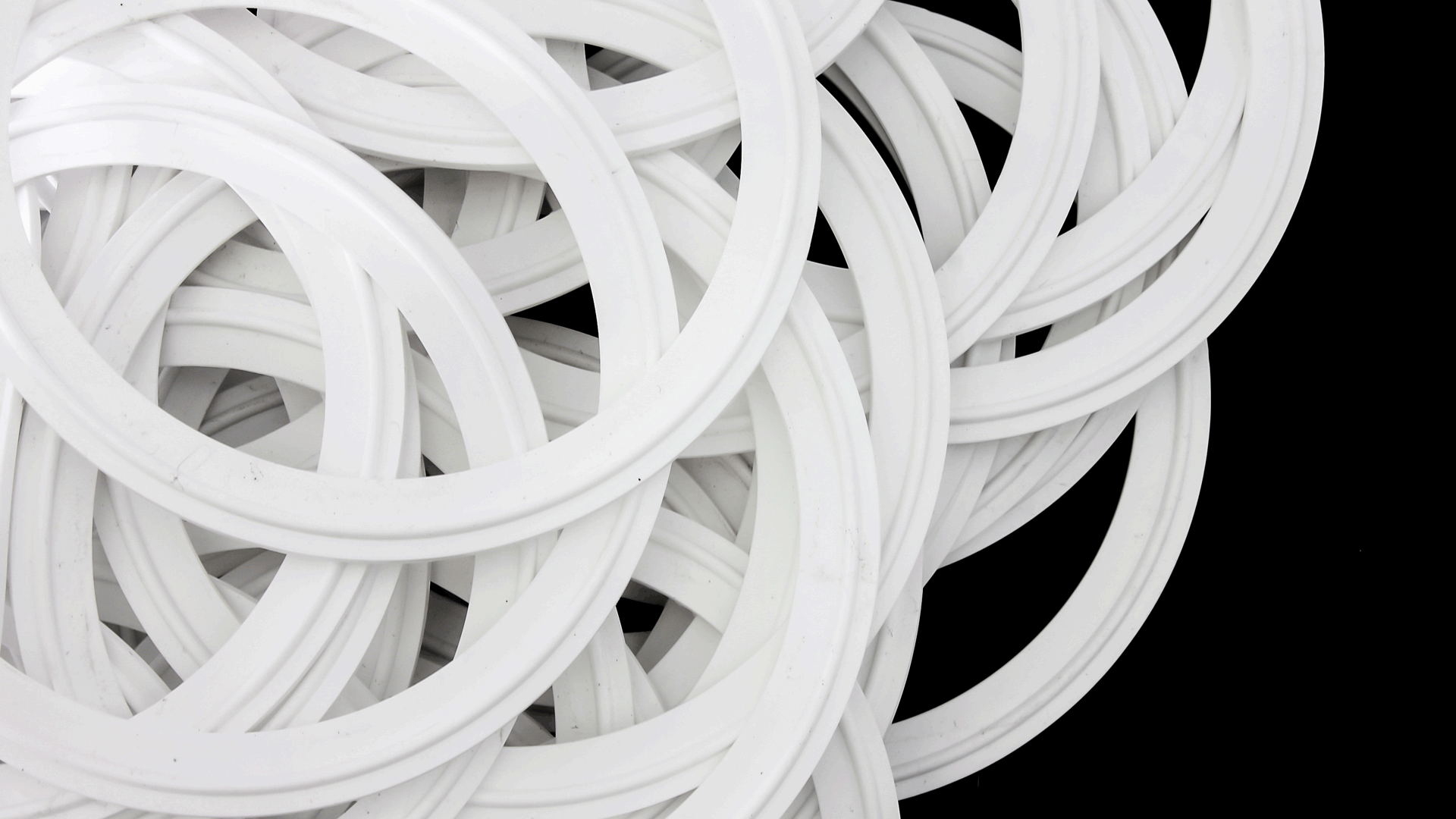

Sanitary Gaskets

Sanitary gaskets are tailored to the stringent requirements of the winemaking industry. Our comprehensive range of sanitary gaskets play a pivotal role in maintaining the highest levels of hygiene, safety, and product integrity.

Why Choose Sanitary Fittings?

We’ve got the experience in the sanitary industry that sets us apart from other providers of winemaking equipment

Custom Fabrication Capabilities

Large Selection of Products and Inventory

Same Day Shipping on Most Orders

Exceptional Customer Service

FAQs for Winemakers

Common questions about hygienic design, winery components, and processes

What types of hoses are best for wine transfer and processing?

We offer food-grade hoses including food-grade PVC, silicone (ideal for heat resistance and flexibility), reinforced rubber, stainless-steel braided PTFE, and crush-resistant hoses; each suited for different stages of winemaking.

Read more about winery hoses, “Five Hoses Used in Wineries“.

Do you provide fittings for small repairs and large facility upgrades?

Yes. With no minimum order requirements, Sanitary Fittings supports everything from single-part emergency repairs to full facility overhauls. Whether it’s one gasket or an entire system of valves and hoses, we have you covered.

Why is 316L stainless steel the material of choice for winemakers?

316L stainless offers superior corrosion resistance and hygienic performance, critical for systems handling sensitive pharmaceutical ingredients. It maintains integrity during cleaning and sterilization processes.

Learn more about, “304 vs 316 Stainless Steel“.

Are your fittings compatible with CIP (Clean-in-Place) systems?

Yes. Our stainless steel fittings are engineered to withstand the high temperatures, pressures, and chemical agents used in CIP and SIP processes. This ensures easy sanitation without needing to dismantle your processing line, helping maintain hygienic integrity and reduce downtime.

Learn more about, “Clean In Place (CIP) Essentials for Manufacturers“.

How can I prevent wine contamination during transfers?

Do I need a sanitary centrifugal pump for winemaking?

Yes. Centrifugal pumps are a workhorse in wineries, making wine transfers faster, smoother, and more consistent. A sanitary centrifugal pump is designed specifically for hygienic applications, preventing contamination while handling delicate liquids like wine with minimal agitation. At Sanitary Fittings, we offer a full range of sanitary centrifugal pumps built to meet 3-A, FDA, and USDA standards—ideal for racking, bottling, or general liquid movement throughout your winery.

Wine-Related Blog Posts

Winemaking components, hygienic guides, sanitary design, and more

Five Hoses Used in Wineries

Wineries typically use a variety of hoses to facilitate different processes within the winemaking industry. Here are some commonly used hoses in wineries:...

Best Practices for Cleaning and Maintaining Sanitary Sample Valves

Product quality and safety hinge on maintaining your sanitary equipment. Sanitary sample valves that are widely used in the food, beverage, and...

Best Practices for Cleaning and Maintaining Your Washdown Station Hose

Best Practices for Cleaning and Maintaining Your Washdown Station Hose In any sanitary processing facility, washdown stations and hoses are essential...