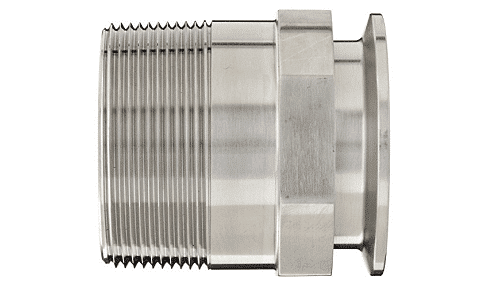

Choosing the right type of fitting is important for system integrity, safety, and compliance. One widely used fitting style is the NPT fitting. We’ll cover more about what NPT stands for, when to use NPT fittings, and what industries usually...Read More

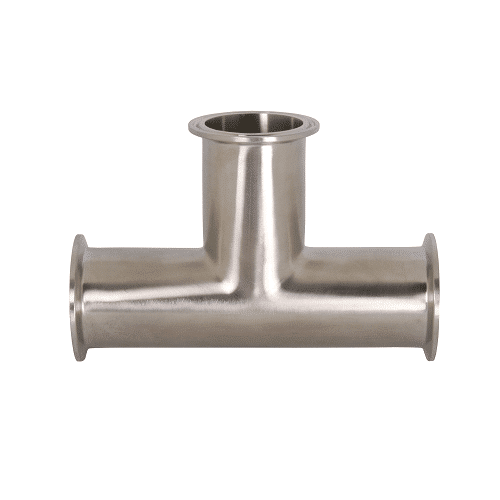

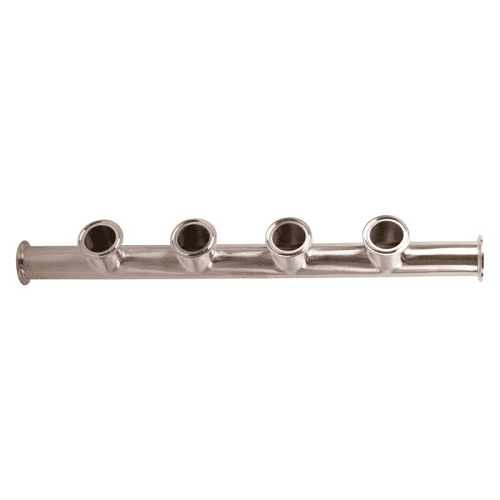

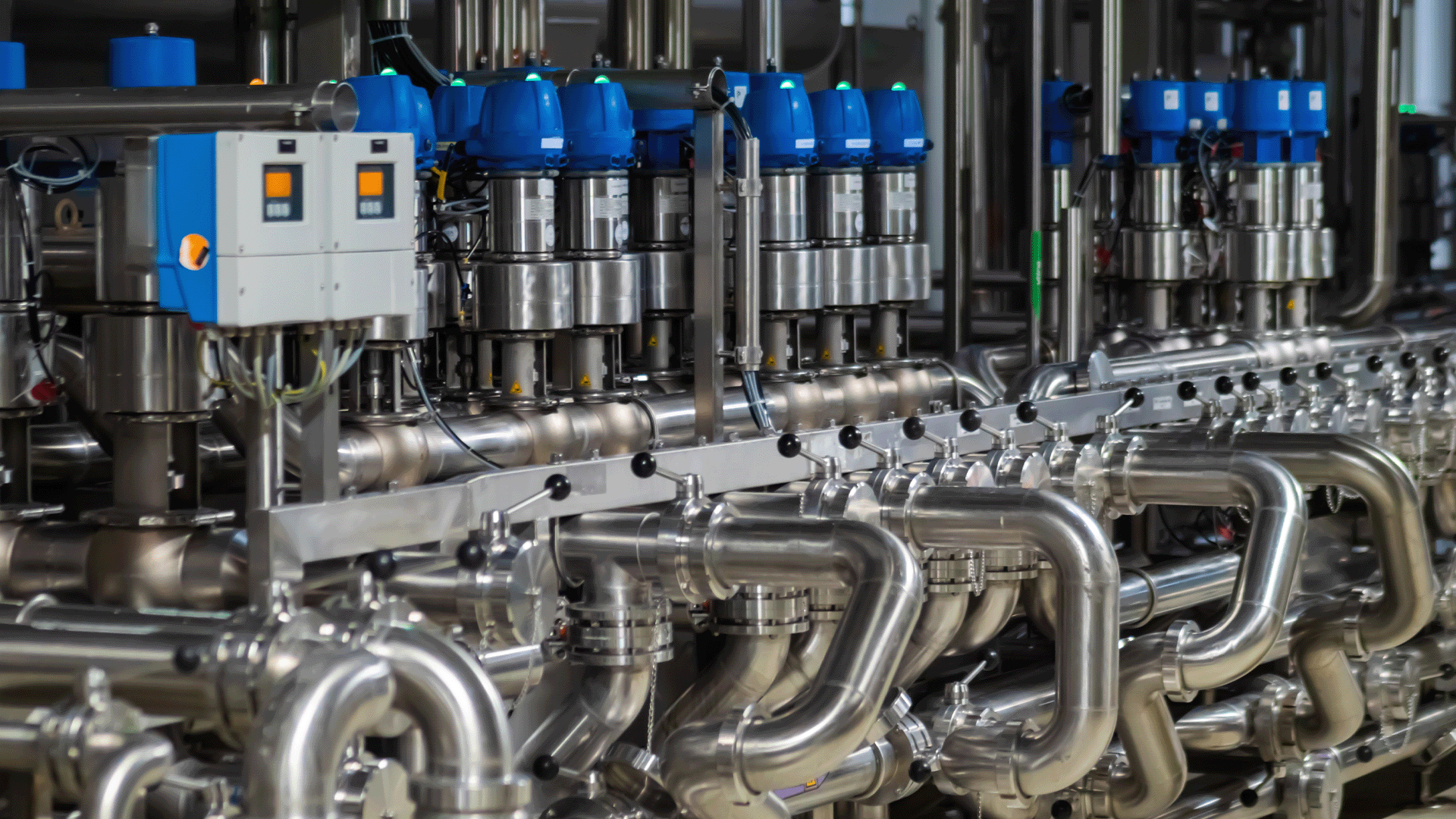

Tri-Clamp Fittings

Stainless steel tri-clamp fittings are the most popular style of process line equipment used within the food, beverage, and pharmaceutical industries. These fittings quickly create a leak-proof connection to allow for easy assembly, routine maintenance and inspection.

Tri-Clamp connections require a gasket and clamp to complete a leak-proof seal. To learn more please see our Frequently Asked Questions or read our Ultimate Guide to Tri-Clamp Fittings

Available in both 304 and 316L stainless steel alloys (what’s the difference) and manufactured in accordance with 3A Standards. Material Test Reports (MTRs) available upon request. Sanitary Fittings has access to a large amount of inventory so most orders include same day shipping.

Products

Showing 1–12 of 61 resultsSorted by popularity

-

Tri-Clamp Brewery Hose Adapters (14MPHRL)

-

Tri-Clamp Long-Weld Ferrule (14AM7)

-

Tri-Clamp Short Ferrule (14WMP)

-

Single-Pin Heavy Duty Clamp (13MHHM)

-

Light Duty Tank Ferrules (14WLMP)

-

Heavy Wall Tank Weld Ferrule (14MPW)

-

Roll-On Expanding Ferrules (14RMP)

-

Tri-Clamp Hose Adapters (14MPHR)

-

Tri-Clamp Thermometer Cap (23BMP)

-

High Pressure Tri-Clamp (13MHP)

-

Tri-Clamp End Caps (16AMP)

-

90° Tri-Clamp Elbow (2CMP)

Related Blog Posts

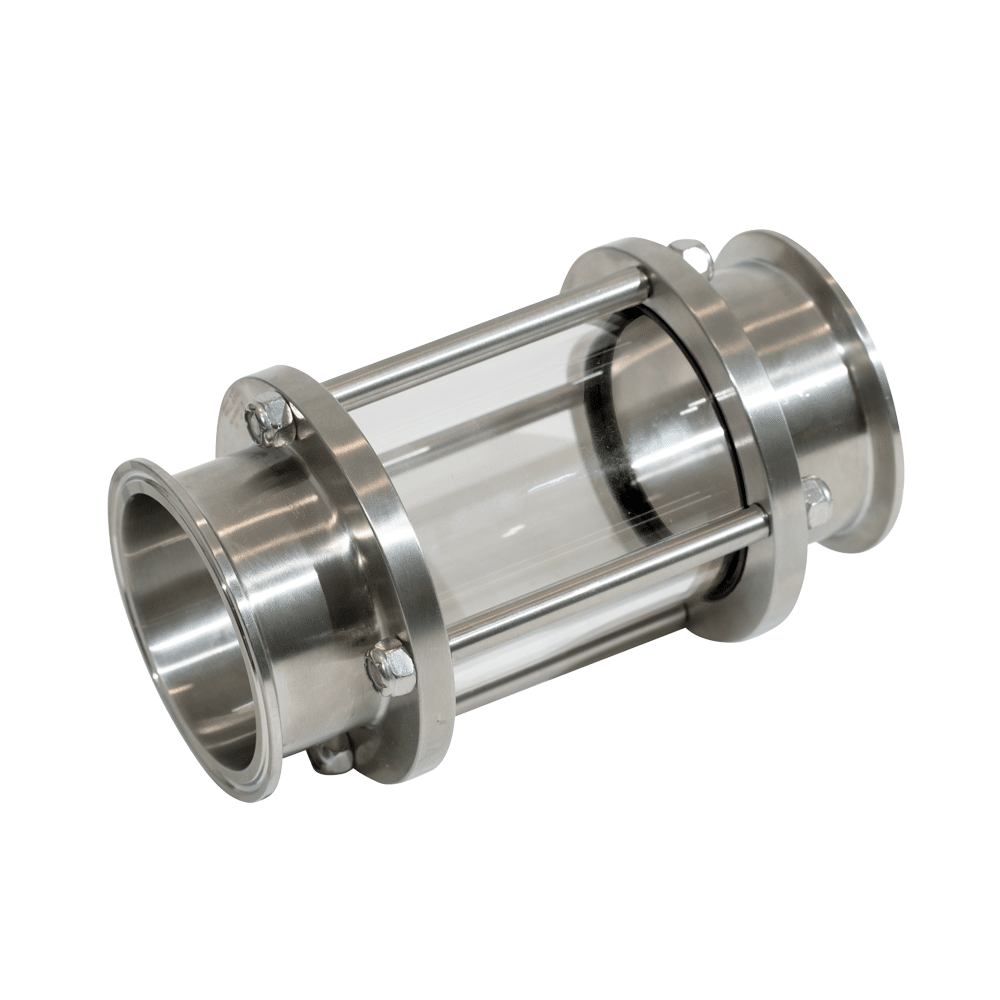

See What’s Flowing: A Practical Guide to Tri-Clamp Sight Glasses

Why Visibility Matters In sanitary processing, losing visual feedback can mean the difference between hitting batch specifications or scrapping a product. A tri-clamp sight glass gives operators a window into the line, with no tools, no shutdown, and no compromise...Read More

Understanding Good Manufacturing Practices (GMP) in Sanitary Production

In highly regulated industries like food, beverage, and pharmaceutical production, maintaining quality and consistency is non-negotiable. One of the foundational frameworks supporting these goals is Good Manufacturing Practices, more commonly referred to as GMP. Whether you’re designing a new production...Read More