In any sanitary processing facility, washdown stations and hoses are essential tools for maintaining sanitary working environments, ensuring that surfaces, equipment, and floors are kept free of residues and contaminants. While these hoses work hard, they also require regular care themselves to function reliably and last longer.

The most important methods for cleaning and maintaining your washdown station hoses. Following these simple practices will help protect your investment, minimize downtime, and uphold the strict sanitary standards your facility demands.

1. Rinse Thoroughly After Every Use

After each washdown session, it’s best practice to rinse your hose with clean water. This step flushes out any remaining chemicals, detergents, or residues inside the hose and nozzle that could otherwise cause buildup or degradation over time. A quick rinse immediately after use is one of the simplest ways to extend hose life.

2. Inspect the Hose Regularly for Wear

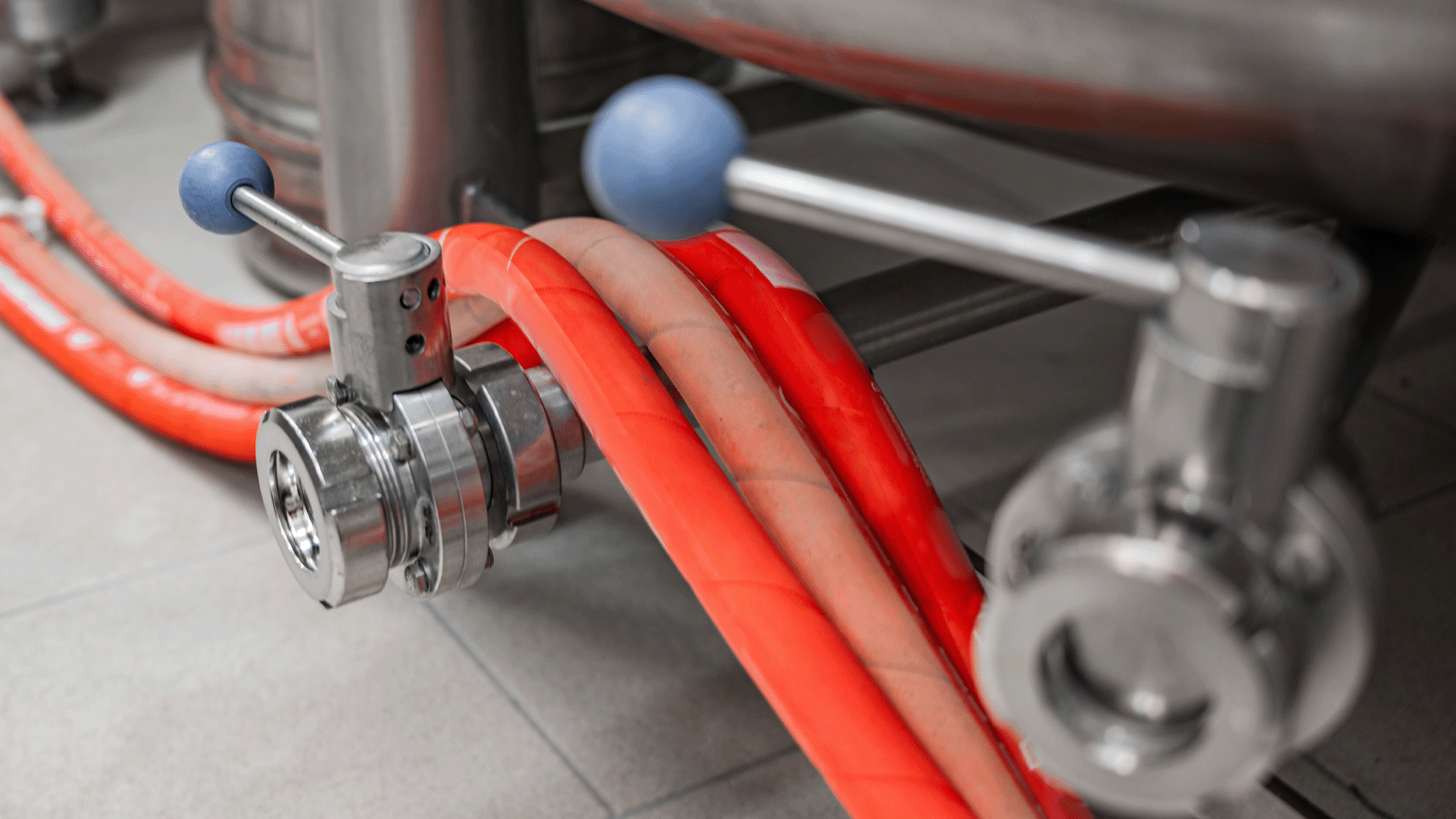

Routine inspection is key. Look for kinks, cracks, abrasions, or leaks along the hose length. Pay close attention to the coupling ends and the nozzle, which often endure the most stress. Early detection of wear allows you to replace or repair components before they cause failures during critical cleaning operations.

3. Store the Hose Properly

Improper storage is one of the most common causes of premature hose damage. Always coil the hose neatly and hang it on an appropriate hose rack or reel. Avoid leaving it lying on the floor where it can be crushed, run over, or contaminated. Storing your hose correctly helps prevent kinking and protects it from environmental hazards.

4. Use the Correct Cleaning Agents

Be mindful of the cleaning agents used with your washdown hose. Harsh chemicals incompatible with the hose material can cause deterioration, leaks, or sudden failures. Always refer to the hose manufacturer’s chemical compatibility guide and select cleaning solutions that won’t damage the hose lining or exterior.

5. Sanitize Periodically

In addition to routine rinsing, it’s important to periodically sanitize the hose itself, especially in high-purity or food-contact environments. Use an approved sanitizing solution and follow your facility’s cleaning protocols to prevent microbial buildup inside the hose.

6. Replace Worn Parts Promptly

No matter how diligent your maintenance routine is, hoses and nozzles will eventually wear out with regular use. Timely replacement of aging or damaged hoses reduces the risk of unexpected downtime and ensures you maintain the hygienic conditions your process requires.

Keep Your Facility Clean and Compliant

A well-maintained washdown hose is an indispensable asset in any sanitary production facility. By incorporating these cleaning and maintenance practices into your standard operating procedures, you help ensure reliable performance, a longer hose lifespan, and continued compliance with industry sanitation standards.

If your current washdown hoses are showing signs of wear or you need to upgrade your washdown station, explore our full range of washdown stations and accessories. Our high-quality hoses are designed to withstand rigorous cleaning tasks while meeting the strict sanitary requirements of your industry.