In any sanitary processing facility, maintaining cleanliness is not optional; it’s critical. Washdown hoses play a pivotal role in achieving the high hygiene standards that are expected. But not all hoses are created equal. Understanding what sets a high-quality washdown hose apart can help ensure your facility stays clean, compliant, and safe. Learn more about washdown stations by reading our Ultimate Guide to Washdown Stations.

1. Durable Construction

A quality washdown hose should withstand the constant wear and tear of daily use. Look for hoses reinforced with multiple layers and abrasion-resistant covers. This durability ensures the hose holds up under frequent drag, bending, and high-pressure cleaning, reducing the risk of premature failures and costly downtime.

2. Temperature and Pressure Ratings

Sanitary washdown often involves hot water or steam cleaning. Hoses used for these applications must tolerate elevated temperatures and pressures without degrading. Always check that the hose you choose is rated for the maximum temperatures and pressures typical in your cleaning routines to ensure both safety and longevity. A good option for a hose that can handle temperature and pressures is our Fortress 300 Washdown Hose.

3. Flexibility and Ease of Handling

In busy production environments, hoses need to be maneuvered around equipment, corners, and tight spaces. A good washdown hose remains flexible even in cooler conditions and resists kinking, allowing staff to clean effectively without fighting stiff or tangled lines. A great option for a flexible washdown station hose is our Strahman Heavy-Duty Double-Lined Washdown Hose.

4. Non-Marking, Smooth Cover

Hoses used in sanitary zones must not leave marks on floors, walls, or equipment. A smooth, non-marking outer cover protects surfaces and prevents contamination. Additionally, smooth covers are easier to clean, ensuring that the hose itself does not harbor bacteria or debris. Our Strahman Premium Washdown Hose is a great option for those looking for a smooth hose.

5. Compliance with Food and Beverage Standards

For food, beverage, and pharmaceutical facilities, hoses should comply with FDA, USDA, or other relevant sanitary standards. Using certified hoses helps protect product integrity and supports your facility’s compliance with stringent regulatory requirements.

Industries That Rely on Washdown Hoses

Washdown hoses are indispensable across many sanitary processing sectors:

- Food & Beverage Processing: For cleaning production lines, conveyors, and workstations.

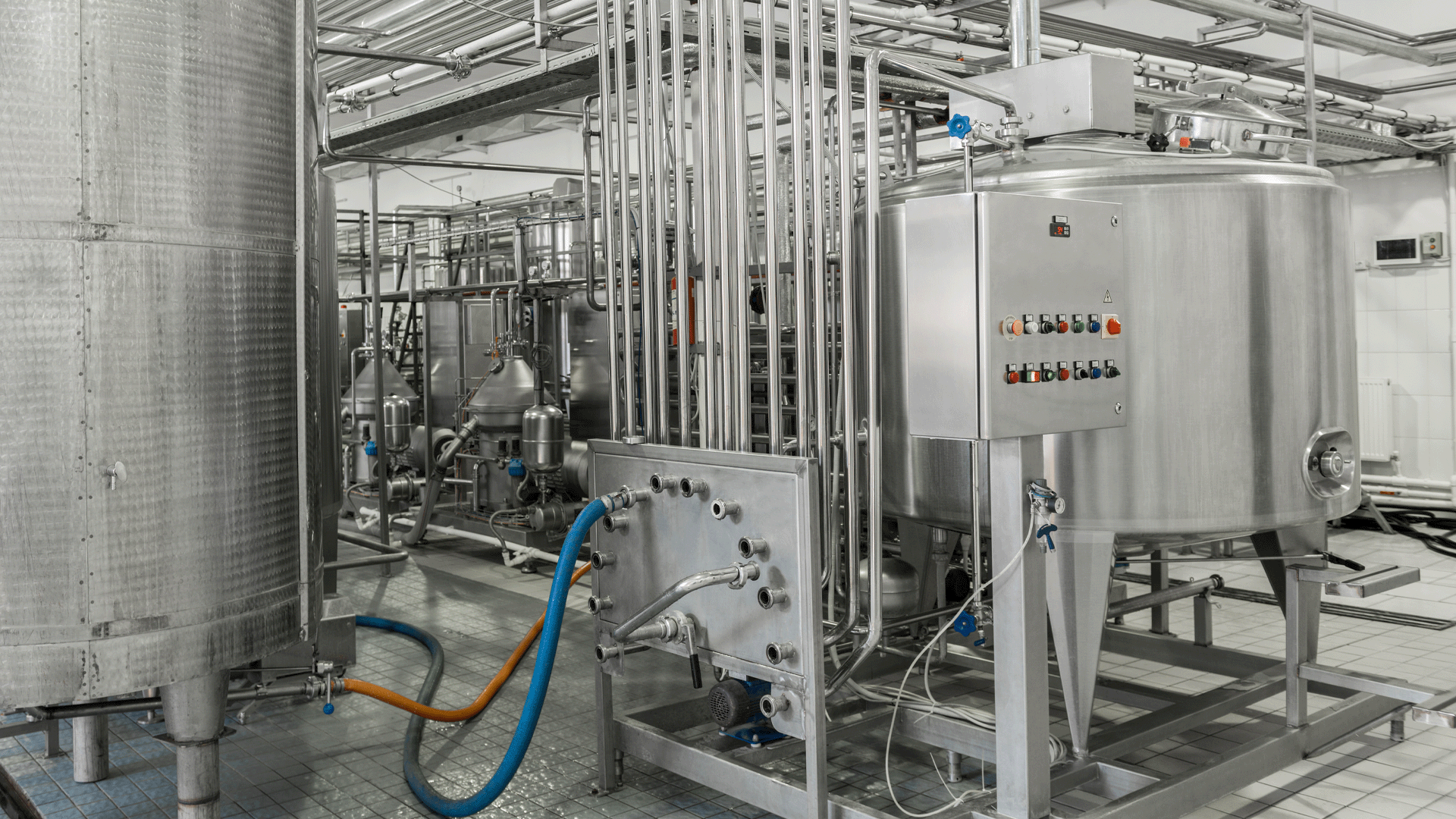

- Dairies and Breweries: To wash vats, tanks, and kegs thoroughly.

- Pharmaceutical Manufacturing: To maintain sterile conditions in cleanrooms and production suites.

- Commercial Kitchens & Meat Processing: For routine sanitizing of floors, prep areas, and equipment.

Why Choose Washdown Hoses Over Standard Hoses?

Unlike general-purpose industrial hoses, washdown hoses are built with sanitary cleaning in mind, and can:

- Handle repeated exposure to hot water and cleaning chemicals.

- Resist kinks and abrasions in demanding environments.

- Meet regulatory and food safety standards.

- Maintain flexibility and user comfort.

Investing in the right washdown hoses ensures cleaning tasks are safer, faster, and more effective, contributing directly to a cleaner production environment and reduced contamination risks.

Find the Right Washdown Hose for Your Facility

We offer a selection of high-quality washdown hoses, carefully chosen to meet the demands of modern sanitary facilities. Pair your hose with our washdown stations, nozzles, and accessories to build a complete, reliable cleaning system for your facility.