Choosing the right type of fitting is important for system integrity, safety, and compliance. One widely used fitting style is the NPT fitting. We’ll cover more about what NPT stands for, when to use NPT fittings, and what industries usually incorporate them in their facilities. Already know the basics? Read our post, “How to Measure NPT Fittings”

What Does NPT Stand For?

NPT stands for National Pipe Thread. This is a standardized threading system used for joining pipes and fittings in North America. NPT threads are tapered or straight, meaning they tighten as they are screwed together, creating a pressure-tight seal without the need for additional sealing mechanisms, but thread sealant or tape is often used for added protection. Learn what the difference is between National Pipe Tapered (NPT) vs National Pipe Straight (NPS).

Who Uses NPT Fittings?

NPT fittings are a staple in a wide range of industries. While they’re not typically considered “sanitary” in the strictest sense, they’re widely used in the following sectors:

- Food & Beverage: Often used in non-contact utility lines such as Clean In Place (CIP) systems, water lines, and cleaning fluid supply lines.

- Biopharmaceutical: Commonly found in auxiliary systems like air and steam utilities or process support lines.

- Chemical Processing: Used in both product and utility lines where a tight mechanical seal is necessary.

- Industrial Manufacturing: Frequently used in instrumentation, air, and gas systems throughout production facilities.

How Are NPT Fittings Used in Production Facilities?

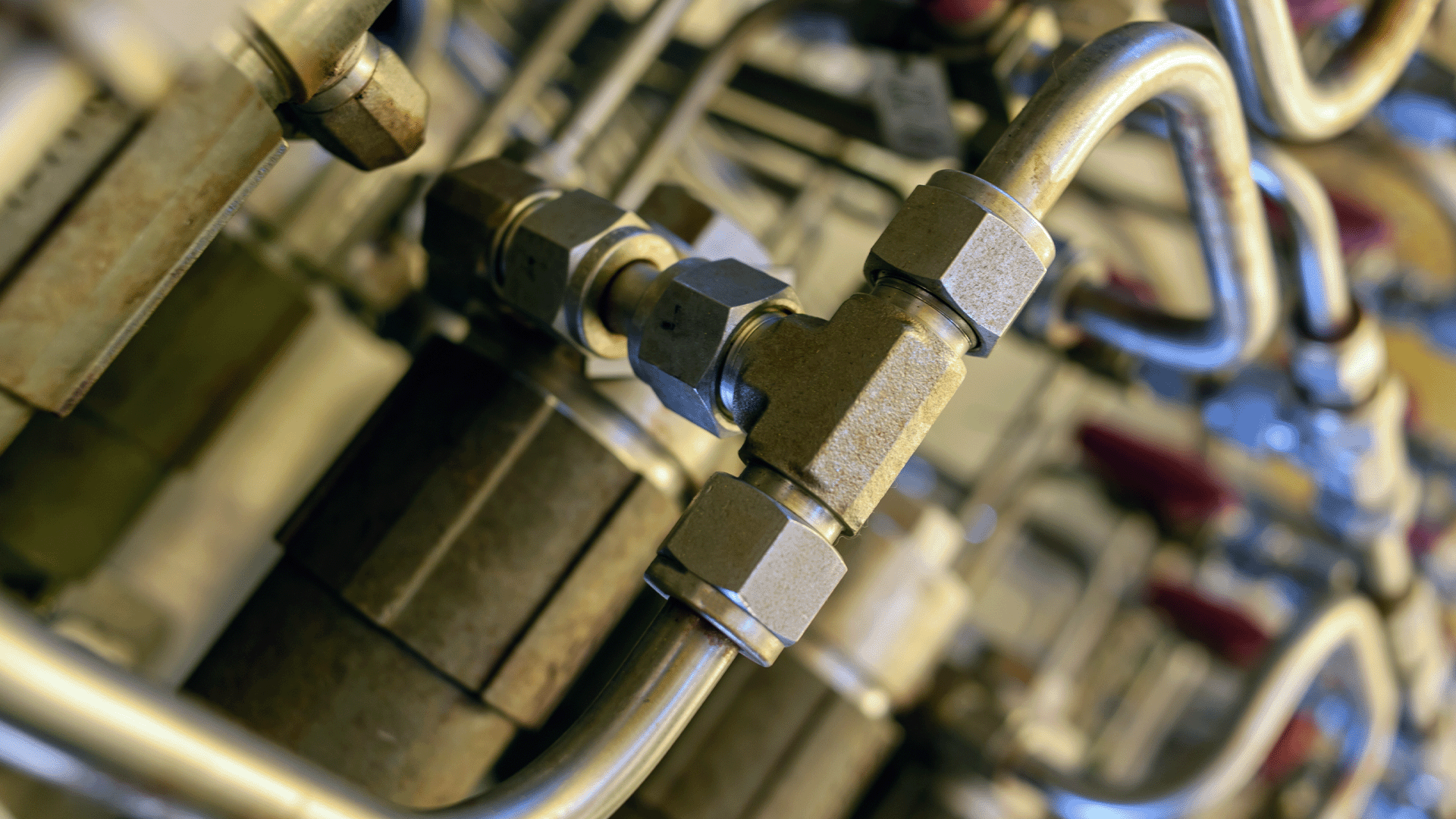

NPT fittings are designed for use in process systems where a threaded, pressure-rated connection is preferred. These fittings are typically found in piping systems that do not require frequent disassembly or cleaning. In many facilities, NPT connections are used to secure instrumentation such as pressure gauges, thermowells, flow sensors, or to plumb air and water lines in utility spaces.

The threaded nature of NPT fittings makes them suitable for applications where vibration, pressure, and temperature changes are present. Their mechanical seal and durability make them a go-to solution for permanent or semi-permanent installations.

When to Choose a Different Connection Type

While NPT fittings are versatile, they are not always the best choice for every sanitary application. Here are a few scenarios when you might want to consider an alternative, such as a Tri-Clamp connection:

- Frequent Cleaning: Tri-Clamp fittings are designed for easy disassembly and cleaning, making them the preferred choice for product-contact systems in sanitary processing.

- Regulatory Compliance: In highly regulated environments like pharmaceutical production, Tri-Clamp and other sanitary connections are often required to meet hygienic standards.

- Tool-Free Maintenance: Tri-Clamp connections don’t require tools to assemble or disassemble, reducing maintenance time and improving safety.

In short, NPT fittings are ideal for permanent or utility systems, while Tri-Clamp connections are better suited for high-purity, product-contact processes.

Need Flexibility? Try Our Tri-Clamp to NPT Adapters

One of the most common challenges in mixed-connection systems is finding a secure and hygienic way to bridge NPT and Tri-Clamp fittings. That’s where our Tri-Clamp to NPT adapters come in.

These adapters allow you to connect a Tri-Clamp fitting on one side and a male or female NPT thread on the other, making them ideal for hybrid systems or when upgrading part of your process line. Whether you’re integrating new instrumentation, retrofitting legacy equipment, or adding sanitary access points, our adapters offer the versatility you need with the sanitary quality you expect.

Explore our full selection of NPT fittings to streamline your operations and minimize system downtime.

Explore Our Selection of NPT Pipe Fittings

If your operation calls for threaded pipe fittings that offer strength, reliability, and wide industry compatibility, our NPT pipe fittings are the perfect solution. We carry a wide variety of options including elbows, tees, couplings, reducers, and adapters, all manufactured from high-quality stainless steel to ensure durability and corrosion resistance.