Sanitary Sample Valves: What They Are, How They Work, and When to Use Them In hygienic processing, representative samples are essential for quality control, release testing, and troubleshooting. Sanitary sample valves are purpose-built to draw those samples safely and repeatably...Read More

Industrial, Fillable Gauges

At its core, a fillable pressure gauge operates on a straightforward principle: the measurement of pressure within a system. Unlike conventional pressure gauges, which typically utilize a Bourdon tube or diaphragm mechanism to gauge pressure, fillable pressure gauges feature a unique design. These gauges contain a chamber that can be filled with a suitable fluid, often glycerin or silicone oil, which then transmits pressure to the gauge mechanism. This fluid-filled system enhances accuracy, dampens vibration, and provides better resistance to fluctuations in pressure.

Read our blog post: Understanding Industrial Fillable Pressure Gauges: A Comprehensive Guide

Products

Showing all 5 resultsSorted by popularity

-

Reotemp® Stainless Steel Industrial Fillable Gauge with 2.5″ Dial (PM25C)

-

Reotemp® Stainless Steel Industrial Fillable Gauge with 1.5″ Dial (PM15C)

-

Reotemp® Stainless Steel Industrial Fillable Gauge with 2″ Dial (PM20C)

-

Reotemp® Stainless Steel Heavy Duty Repairable and Fillable Gauge with 4″ Dial (PR40S)

-

Reotemp® Stainless Steel Heavy Duty Repairable and Fillable Gauge with 6″ Dial (PR60S)

Related Blog Posts

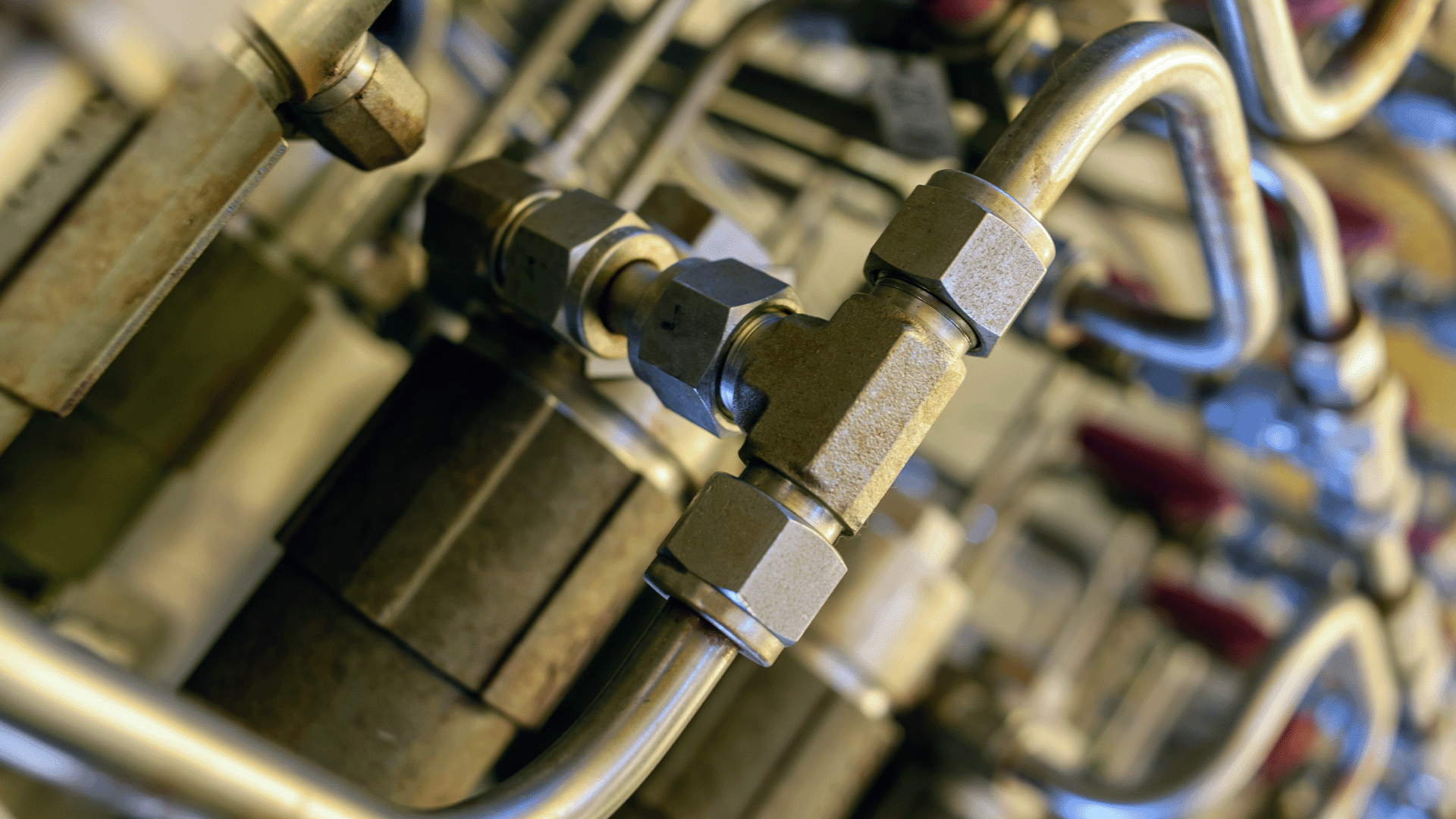

Understanding NPT Pipe Fittings: When and Where to Use Them

Choosing the right type of fitting is important for system integrity, safety, and compliance. One widely used fitting style is the NPT fitting. We’ll cover more about what NPT stands for, when to use NPT fittings, and what industries usually...Read More

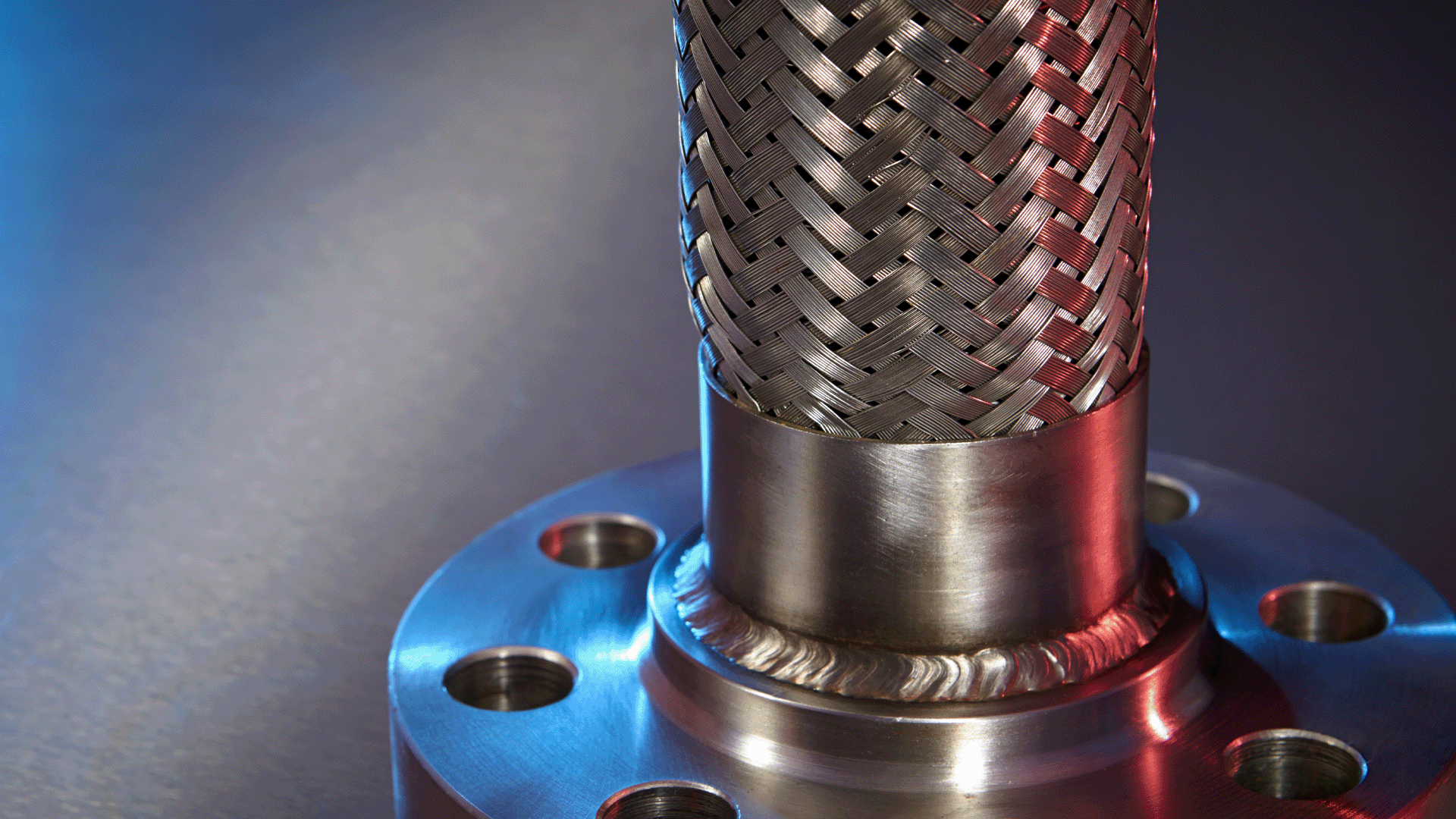

Stainless Steel Braided Hoses: Strength for Sanitary Processing

In hygienic processing environments — whether you’re blending beverages, fermenting biologics, or packaging dairy — every component in the fluid path must deliver uncompromising cleanliness and reliability. A stainless steel braided hose does exactly that: it marries a smooth, cleanable...Read More